12-23/2024

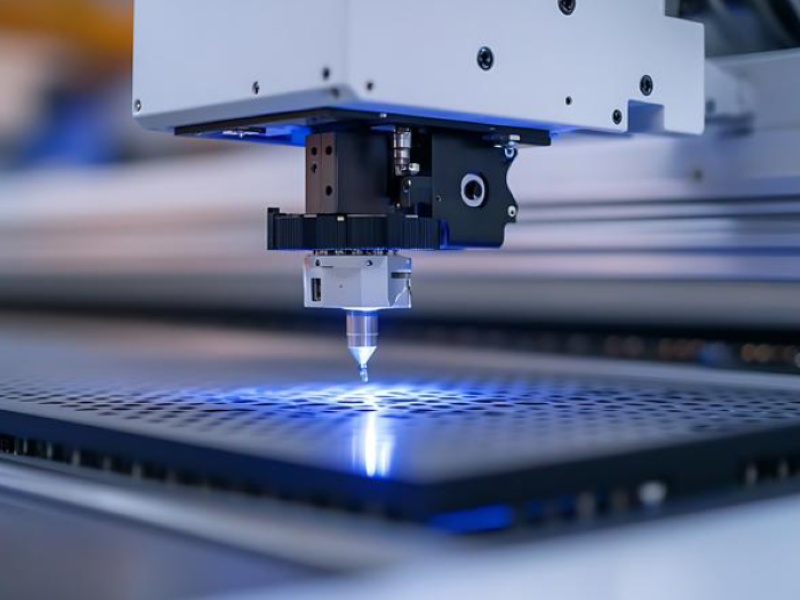

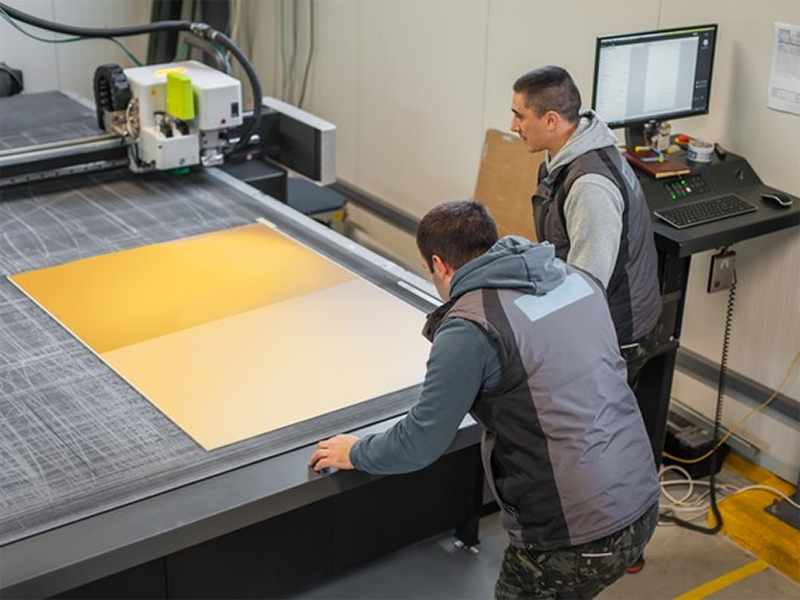

Laser technology is a cutting-edge technology for modern high-end manufacturing. Compared with traditional processing equipment, laser processing equipment, optical communication devices and equipment, laser measurement equipment, lasers, laser medical equipment, laser components and other laser equipment have many comparative advantages such as high precision and high efficiency. Therefore, with the rapid development of laser processing technology, especially the rapid iteration of core component laser technology, the laser power continues to increase, the cost continues to decrease, the range of processable materials continues to expand, and the processing quality and processing efficiency continue to improve. The replacement effect of laser technology on traditional process technology is increasingly prominent, and it plays an important role in the process of industrial transformation and upgrading. From the perspective of application scope, the application of laser processing technology has expanded from the light industrial fields such as food, textiles, and electronics at the beginning to heavy industrial fields such as automobiles, ships, aerospace, aviation, and high-speed rail. Data shows that my country's laser market has achieved more than 6 times growth in the past 10 years, and the market size has grown to 241.532 billion yuan by 2023.