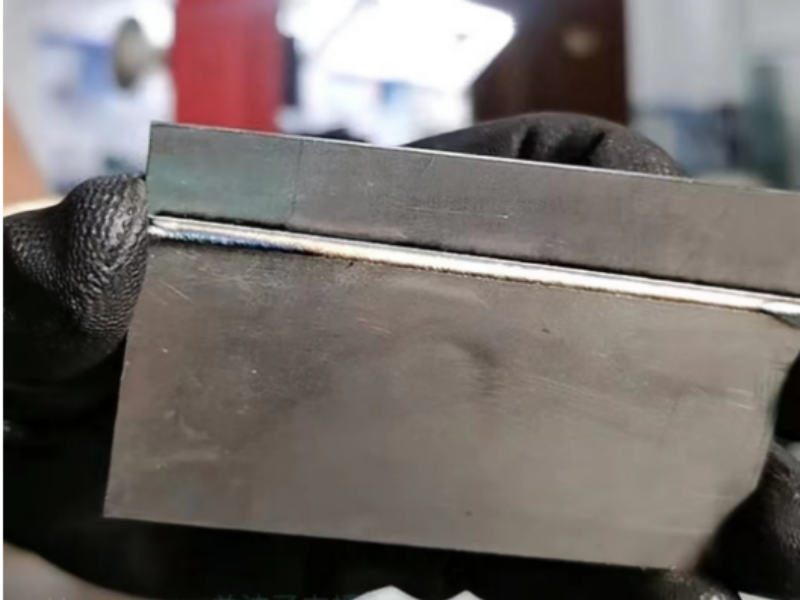

The problem of stainless steel turning black, yellowing, and bluing after welding has always troubled many sheet metal welding industries. From kitchenware to medical equipment to elevator door panels, customers have higher and higher requirements for the consistency of weld color. Many customers often ask us: "Why does fiber laser welding also turn black? Can it really be solved?"

This article is not an enumerated operation manual, but based on our front-line experience in serving customers, it proposes three solutions that are more suitable for fiber laser welding around the causes of stainless steel welds turning black.

Tip: Although weld blackening is a more common problem in traditional welding, it also occurs in fiber laser welding, especially when the shielding gas is not standardized and the power setting is not appropriate.

1. Analysis of the cause of blackening: The "black" you see is not a heat problem, but oxidation

The blackening of the weld is essentially the formation of an oxide film of varying thickness on the surface. This film may be:

The oxygen in the air combines with the metal at high temperature to produce iron oxide/chromium oxide. Metal impurities react and remain in the heat-affected zone. The unstable gas shielding laminar flow causes the welding area to be exposed to the air.

In fiber laser welding, this problem may occur in the following scenarios:

When the thickness of stainless steel material is thin (<2mm). The welding speed is slow and the energy density is too high. The shielding gas angle is unreasonable or the delayed gas closing time is insufficient.

Method 1:

Detailed operation steps:

Shielding gas selection: It is recommended to use argon or nitrogen with a purity of more than 99.99%. Compared with carbon dioxide mixed gases, inert gas can avoid oxide film.

Nozzle angle: Keep the angle between the nozzle and the weld at 30-45°, and the airflow direction should be close to the direction of the weld, not vertical or scattered.

Delayed gas closing setting: After the welding is completed, the gas continues to blow for 2-3 seconds to avoid direct exposure of the weld to the air during the high temperature stage.

Airflow rate: Adjust to a moderate level (such as 15-20 L/min) to prevent excessive cyclone formation and disturbance of the protective layer.

Why is it effective?

In traditional TIG welding, unstable gas flow is the main cause of blackening, and fiber laser welding is also difficult to escape the risk of oxidation if there is no secondary protection device or the speed is set too high by mistake.

Method 2: Matching power and speed:

Parameter adjustment suggestions:

| Material thickness | Laser power (W) | Welding speed (mm/s) | Spot diameter (mm) |

| 1.0mm | 800–1000 | 25–30 | 0.5 |

| 1.5mm | 1200–1500 | 20–25 | 0.6 |

| 2.0mm | 1500–1800 | 18–22 | 0.6–0.8 |

Do not blindly increase the power to solve the problem of penetration depth, otherwise it is easy to burn blue on both sides of the weld.

For corner welding/lap welding, the power is slightly reduced by 5-10% to avoid burning the bottom after penetration.

What is the difference from traditional welding?

Traditional welders rely on "experience" and visual judgment of arc heat, while fiber laser welding must strictly control heat input. "Overheating" does not necessarily weld better, but is more prone to oxidation.

Method 3: Rapid cooling or polishing after welding:

If slight blackening of the weld has occurred, post-weld treatment is recommended. Especially in scenes with high requirements for appearance, such as elevators and stainless steel decorative parts. There are two ways to deal with it:

1. Rapid cooling:

At the end of welding, use spray or forced air cooling to quickly remove heat and reduce the continuation of high-temperature oxidation.

2. Mechanical/electrochemical polishing:

Use an electrolytic polisher or stainless steel weld cleaning machine to restore the original color of the metal and remove the black oxide layer.

Note:

This method is suitable for visible parts. If it is a sealed part, use it with caution to prevent residual liquid from affecting the subsequent sealing.

Extended supplement: 3 advantages of fiber laser welding over traditional welding in preventing blackening:

| Comparison points | Traditional arc welding | Fiber laser welding |

| Heat affected zone | Large, easy to overburn | Fiber laser welding |

| Gas shielding | Unstable, easy to miss protection | Small, precise control |

| Post-weld cleaning | More grinding required | Almost no post-welding treatment |

FAQ:

Q: Will fiber laser welding also turn black?

A: Yes, especially when the parameters are set improperly or the gas protection is not in place. But the overall blackening probability of laser welding is much lower than that of traditional welding.

Q: Why does my laser welder still have black spots after changing to argon?

A: You need to check the nozzle direction, gas purity, and delayed gas shut-off time. Many problems lie in the detailed settings.

Q: Will nitrogen be better than argon?

A: On some stainless steel with a thickness of less than 1.5mm, nitrogen can indeed improve the protection, but it is necessary to prevent nitrogen embrittlement from affecting the strength.

If you encounter other specific problems during welding, please leave a message or contact our application engineer team. We will provide parameter recommendations and equipment adaptation guidance based on your application scenario.