In the field of handicrafts and decorations, jade has always occupied an important position because of its unique beauty and deep cultural value. Laser marking technology is also relying on its efficient and accurate characteristics. It is becoming an essential tool in the jade carving process. The laser marking function realizes the marking of complex patterns, texts or serial numbers, while minimizing the degree of damage to the material. However, in the face of a wide variety of laser marking equipment on the market, how do we choose the best model for jade materials with high hardness and precise structure is still a challenge facing the industry. Today we will talk about the key steps in choosing a split laser marking machine to help users choose the most suitable marking equipment based on the characteristics of jade.

The first step in choosing a suitable laser marking machine is to clarify our own needs. We have to confirm the type of jade marked (such as jade, Hetian jade, etc.) at the beginning. The hardness and transparency of different jade stones vary significantly. For example, jade has a Mohs hardness of 6.5-7, so you need to choose a small fiber laser engraver that can handle high-hardness materials.Then we must clearly mark the content (such as fine patterns or tiny text), set the depth, clarity, and size standards, and make the mark lasting and beautiful. In order to evaluate production efficiency, calculate the average marking time (such as the time-consuming engraving of a single piece), and adjust the small fiber laser engraver parameters according to the speed of the production line to avoid bottlenecks. Verifying material compatibility and output efficiency through sample testing is the key to avoiding late adjustments.

For jade materials, ultraviolet small fiber laser engraver is a very ideal choice. Our small fiber laser engraver produces very little thermal effect. It can achieve fine sub-millimeter marking on the surface of jade to avoid cracking or discoloration caused by thermal damage. Through a high-energy-density beam of light, ULTRAVIOLET lasers can accurately act on the surface of jade materials, causing controllable physical changes (such as surface ablation), rather than chemical changes, to ensure high marking clarity and sharp edges. In contrast, although traditional fiber lasers are highly versatile, they may introduce the risk of overheating to sensitive hard materials such as jade. When choosing the UV small fiber laser engraver type, it is necessary to combine the wavelength and power parameters to enhance the engraving details.

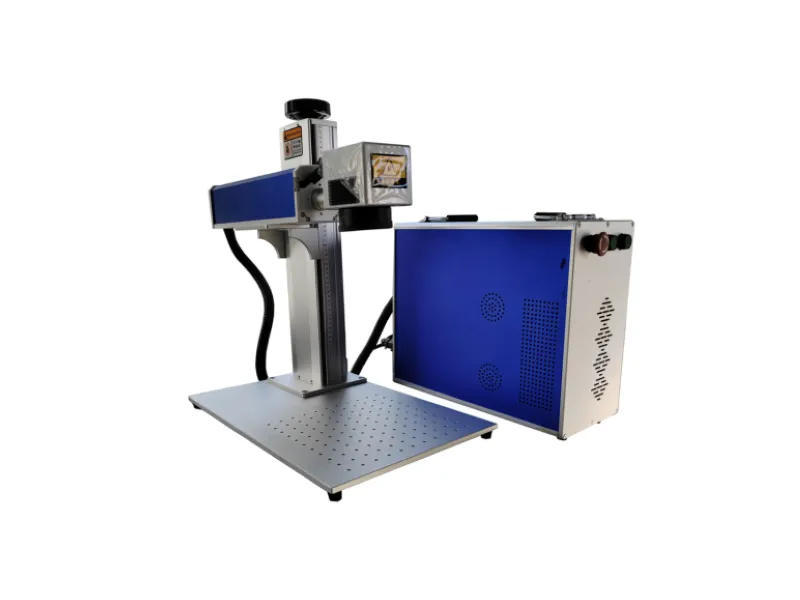

The structural advantages of the split small fiber laser engraver (the laser generator is separated from the marking head) increase a certain degree of flexibility, but the performance parameters may directly affect the quality of jade engraving. The laser power should match the marking depth requirements (for example, the range of 30W-50W is suitable for shallow fine engraving). The power of the split small fiber laser engraver is too high, which may cause excessive ablation of jade. The scanning speed of small fiber laser engraver needs to be synchronized with the production rhythm (a high-speed scanning system is recommended) to make the marking consistent and throughput. An efficient cooling system (such as air-cooled or water-cooled) is a very critical point. It can maintain the stable operation of the small fiber laser engraver for a long time and prevent temperature fluctuations from affecting the beam accuracy. Conducting field tests to verify the performance of these parameters on jade samples is an important step to ensure the reliability of practical applications.

Through our above method, you can efficiently choose a split small fiber laser engraver , giving full play to the precise and efficient advantages of small fiber laser engraver in jade carving. If you have any questions about our content or are interested in our products, you can come to us for consultation. Our products also support customization. We can provide you with the small fiber laser engraver you need most according to your needs. In the next article, we will continue the application of UV laser engraver in glass materials, so stay tuned.