In the previous article, we introduced "The application of small fiber laser engraving Machines in jade", so today let's continue to look at how small fiber laser engraving machines should be used in glass materials.

In the fields of architecture, decoration and daily necessities, glass products play an important role with their unique transparency and aesthetic value. Whether it is exquisite decorative glass, electronic product screens, or glassware that we use in our daily lives, a clear, long-lasting and non-easy-to-wear logo is very important to it. The precise and non-contact characteristics of laser marking technology have become the best choice to achieve this goal. However, in the face of diverse glass materials (such as ordinary glass, tempered glass or plexiglass), how should we choose the most suitable glass equipment?

Similarly, the first step in choosing a suitable laser marking machine should be to clarify our own needs. Confirm the marking material-the type of glass will directly affect the choice of UV laser engraver. For example, tempered glass has high hardness and needs to be guaranteed that the marking will not cause microcracks; While plexiglass may be more susceptible to thermal deformation. So at this time, we need to set clarity, depth and size standards based on the marking content (such as trademark, production date or serial number). For example, shallow fine marking requires a high-resolution UV laser engraver. To evaluate our production environment: calculate the marking speed to match the rhythm of the production line (such as processing capacity per hour), and consider the ease of operation (such as user-friendly interface). UV laser engraver is particularly suitable for this type of demand because of its low thermal effect, which can achieve non-destructive marking and avoid glass surface damage.

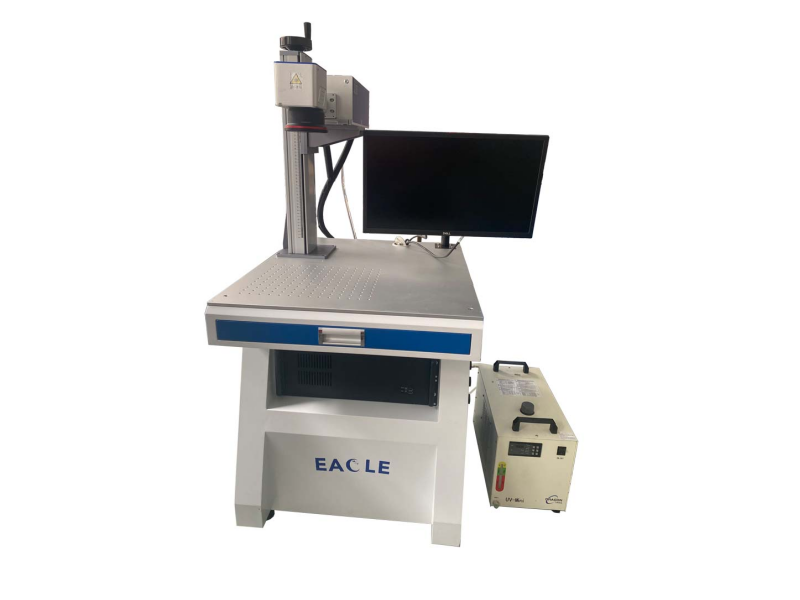

Among all kinds of laser marking machines, we believe that UV laser engraver is the most suitable. This is a laser marking machine designed for sensitive materials such as glass. Its advantage is that the thermal effect generated by the ultraviolet laser is very small, and it can perform sub-millimeter fine engraving (such as complex patterns or tiny text) on the glass surface without causing ablation or deformation of the material. This ensures the durability and aesthetics of the logo, especially suitable for application scenarios such as decorative glass and electronic product screens. Compared with CO2 laser marking machines (suitable for large-area deep etching) or fiber laser marking machines (matching high-speed requirements), UV laser engraver has more advantages in fineness and non-destructive properties, and is an ideal choice for the pursuit of high-quality glass products.

When choosing UV laser engraver, we also need to comprehensively examine the performance parameters: laser power (such as the 20-40W range is suitable for shallow glass marking, too high may cause overheating), scanning speed (high-speed system improves efficiency), and efficient cooling system (such as air-cooled design, which is conducive to ensuring long-term operating temperature stability).

Through these steps, we believe that UV laser engraver can bring high precision and high output to glass products, and improve the overall production efficiency.

In short, choosing the right laser marking machine is the key to improving the quality and production efficiency of glass product marking. With its unique advantages, UV laser engraver has made great achievements in the application of glass products. If you encounter challenges in equipment selection, we welcome your consultation.In the next article, we will continue to explain to you the application of carbon dioxide laser marking machine on plastic and acrylic plates. If you are interested, please continue to pay attention to our article!