Nowadays, the application of laser technology is endless, and various new applications continue to appear. The rapid development of laser technology is gradually penetrating into many aspects of processing and manufacturing.In the current field of precision machining, the application of UV laser marker is also becoming more and more extensive.

The process of ultraviolet laser processing is called the “photoreceptor” effect. High-energy photons directly destroy the chemical bonds of the material through “cold” treatment, and the processed material has smooth edges and very low carbonization.

Therefore, UV laser marker is very suitable for the current fine processing, and its good performance is accepted by many industries, and it has become an important processing method in the field of precision machining.

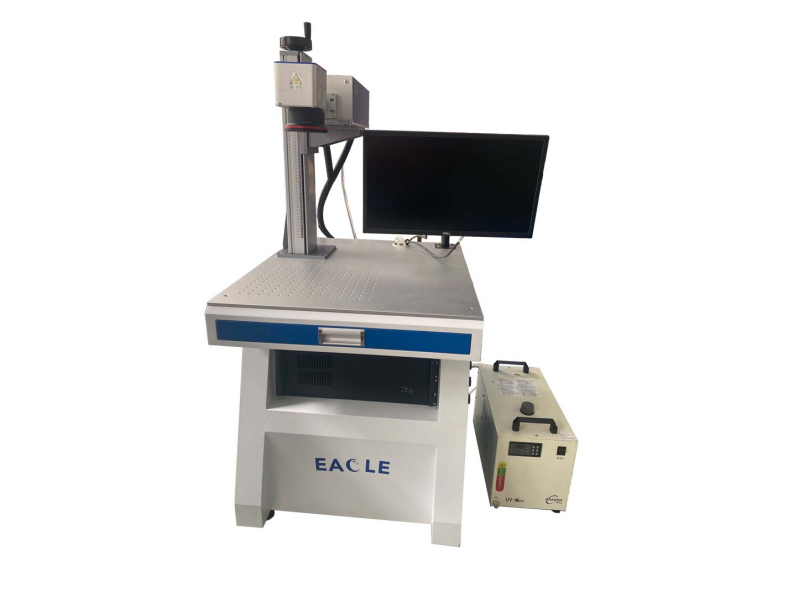

The UV laser marker of our Eagle Laser produces a very small spot, the material deformation caused by marking is small, and the thermal effect of processing is small. Our UV laser marker has high accuracy and little impact on the material. It is used for ultra-fine marking and engraving to prevent microcracks when marking fragile materials. Our UV laser marker control software uses the Windows platform and can read files made by AutoCAD, CorelDRAW, Photoshop and other software. The output power of this UV laser engraving machine is controlled by software and continuously adjustable. The marking effect is good and it is not easy to wear out. The marking process does not produce smoke and dust, which is particularly suitable for operation in a cleaning workshop.

The ultraviolet laser has a very small focus and a small heat-affected zone. Therefore, when processing, it will not affect the surrounding materials on the marking surface. The small laser beam also meets the current needs of refined processing, as well as the processing needs of special fields. It is now the preferred choice for customers in the field of high marking effect.

At the same time, UV laser marker has a wide range of applications and can fine-mark most materials. The processing speed is fast, the efficiency is high, and the stability of the whole machine is good. It can meet mass production and assembly operations. It is now a powerful assistant in the field of refined processing.It has played an important role in the current field of refined processing, providing us with a fast and efficient solution for refined processing now.

UV laser marker is based on a unique low-power laser beam, especially suitable for the high-end market of ultra-fine processing, packaging bottle surface marking of cosmetics, medicines, food and other polymer materials, with fine effects, clear and firm marking, better than ink coding and pollution-free; flexible PCB board marking, scribing; Silicon wafer micropores, blind hole processing; LCD LCD glass QR code marking, glassware surface punching, metal surface coating marking, plastic buttons, electronic components, gifts, communication equipment, building materials and so on.

China's first laser was manufactured in Changchun. Relying on Changchun Institute of Optics, Precision Machinery and Physics (ClOMP), Jilin University, Changchun University of Science and Technology (CUST), Eagle Laser is a high-tech manufacturing enterprise, adhering to the model of customer satisfaction, employee happiness, and value creation, and is committed to building a high-end brand in the laser equipment industry. The business philosophy of serving high-end brands. We focus on the design and production of professional laser equipment such as laser cutting, marking, welding, rust removal, and barrier removal. Eagle has dozens of products, which have the technical advantages of high electro-optical conversion rate, high anti-reverse ability, customized output fiber length, and high beam quality. It has won the trust and praise of the majority of users at home and abroad.