The problem of burrs in the CNC fiber laser cutting machine during processing is often a headache. Many people mistakenly think that it is a problem with the quality of the equipment, but in fact, the generation of burrs is often related to multiple factors.

Generation of burrs:

Burrs refer to excess residue particles left on the surface of metal during the processing of metal products. These burrs will cause the workpiece to be regarded as defective.

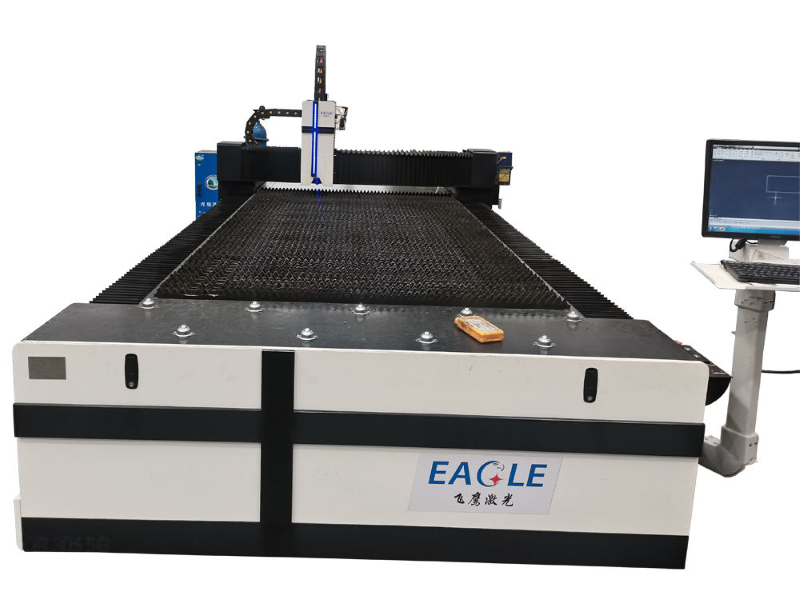

Working principle of CNC fiber laser cutting machine:

CNC fiber laser cutting machine irradiates the surface of the workpiece with a high-energy laser beam to vaporize and evaporate it, thereby achieving cutting. In this process, the use of gas is crucial.

Gas is mainly used to blow off the slag on the surface of the workpiece. If gas is not used during processing, the slag may remain on the cutting surface after cooling, so the purity of the cutting auxiliary gas needs to be high. It is recommended to use high-purity gas and avoid using gas that has been filled twice, because the purity of such gas will be reduced.

Equipment quality:

The quality of the equipment will also affect whether burrs are generated during the cutting process. After purchasing the laser cutting machine, an experienced operator is required to debug the equipment so that the parameters of the CNC fiber laser cutting machine can be adjusted to the best state.

Setting of cutting parameters:

The setting of cutting parameters should not be ignored. After purchasing the CNC fiber laser cutting machine, an experienced operator is required to debug the equipment so that the parameters of the laser cutting machine can be adjusted to the best state.

Methods to solve burrs:

1. Check whether the output power of the CNC fiber laser cutting machine is normal. If it is not normal, maintenance is required.

2. Adjust the focus position of the CNC fiber laser cutting machine if it is found that the position of the laser beam output is offset up and down.

3. Replace the auxiliary cutting gas if it is found that the auxiliary gas purity is not enough.

4. Adjust the processing speed of the CNC fiber laser cutting machine if it is found that the processing speed is too slow.

5. Turn off the CNC fiber laser cutting machine and let the equipment rest for a while before processing. If it is because the laser cutting machine has been working for a long time.

Through the above methods, the burr problem generated during the processing of the laser cutting machine can be effectively solved and the quality of the workpiece can be improved.

The above content is for reference only, and please handle it according to the equipment itself.