What is laser welding? The current development of laser welding technology? What fields can laser welding technology be applied to? What is laser welding?

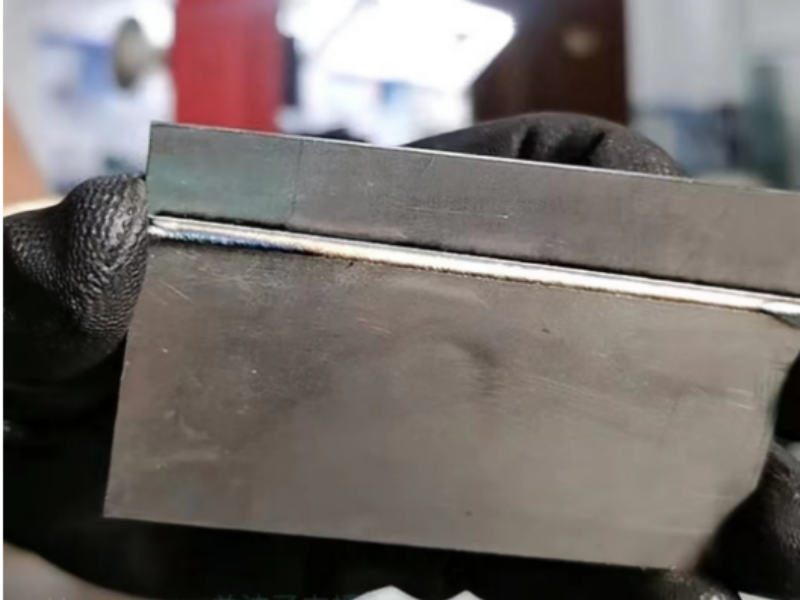

Simply put, laser welding is to heat the surface of the workpiece with laser radiation, the surface heat diffuses to the interior through heat conduction, and then by controlling the width, energy, peak power, repetition frequency and other parameters of the laser pulse, the workpiece is melted to form a specific bath, so as to achieve welding.

Laser welding can minimize the amount of incoming heat required, the range of metallographic changes in the heat-affected zone is small, and the deformation caused by heat conduction is also the lowest.

Non-contact welding, the wear and deformation of the equipment can be minimized. The laser beam is easy to focus, align, and be guided by optical instruments. It can be placed at an appropriate distance from the workpiece, and can be re-guided between the tools or obstacles around the workpiece.

The laser beam can be focused on a very small area, and small and closely spaced parts can be welded. The range of weldable materials is large, and various heterogeneous materials can also be joined to each other.

It is easy to perform high-speed welding with automation, and can also be controlled digitally or by computer. When welding thin or fine-diameter wire, there is no trouble such as back melting.

Table of contents:

Development status of laser welding technology

Metal laser welding technology

Efficient laser welding of copper and copper alloys

Aluminum alloy laser swing welding

The current application of laser welding technology in various fields

Application of laser welding technology in the field of automobile manufacturing

The development trend of laser welding technology

Development status of laser welding technology:

Laser welding technology has been developed along with the development of laser technology. In recent years, new light sources such as blue lasers, green lasers, and femtosecond lasers, as well as new processes such as swing welding and ARM (adjustable ringmode) ring dimmable spot welding, have been continuously introduced, innovatively solving some welding problems in industrial production, which has enabled laser welding to be rapidly promoted and developed in various fields of industrial production.

Metal laser welding technology:

The high energy density of the laser makes it possible to weld some difficult-to-weld metal materials, but there are still some problems with the welding of highly reflective materials such as gold, silver, copper, aluminum, and dissimilar metal materials. The main reasons include:

1.With high reflectance and high thermal conductivity, laser welding requires a higher starting power;

2.In the process of high-power laser welding, it is more sensitive to changes in the surface state of the material, which leads to poor forming of solder joints/welds.;

3.Laser welding speed is fast, which leads to welding defects such as pores inside the weld, especially aluminum and aluminum alloys.

Efficient laser welding of copper and copper alloys:

Copper has excellent electrical and thermal conductivity, and is widely used in the manufacturing fields of electronic products and electric vehicles. Among them, electric motors, batteries, sensors, wiring harnesses and terminals are the most widely used products.

In the past, laser welding of metal materials mainly relied on infrared lasers. However, the thermal conductivity of copper is too high, almost 5 times that of pure iron and 1.7 times that of pure aluminum. The absorption rate of copper to infrared lasers is low. The use of infrared lasers for linear welding has an unstable process window and the largest melting depth fluctuation. Prone to welding splashes, molten metal splashes, pores and large fluctuations in penetration depth and other problems.

Therefore, after the emergence of high-power short-wavelength lasers, visible laser welding and composite welding have become ideal processing methods for highly reflective materials such as copper and copper alloys.

1.Green laser welding:

Green laser is a kind of visible light with a wavelength of 500~560nm. The absorption rate of copper to green light with a wavelength of λ=515nm is as high as 40%, which is about 8 times the absorption rate of infrared light around 1µm, and the energy coupling efficiency is higher, and the sensitivity to the degree of surface oxidation is also reduced.

The use of green laser can significantly reduce the threshold power of copper deep melt welding, the amount of meltblown and splash on the surface of the weld is small, and it is almost unaffected by the welding speed.If you increase beam scanning, beam defocus, and correct laser power modulation, the welding quality can be significantly improved. While the number of weld defects is greatly reduced, the weld surface will be more regular and uniform.

2.Blue laser welding:

The shorter the wavelength, the higher the photon energy, which is conducive to improving the absorption rate of the material to the laser. The wavelength of the blue laser is 400nm~500n. The semiconductor laser based on gallium nitride material can directly produce a laser with a wavelength of 450 nm without further frequency doubling. It has the advantages of simple structure, easy to use, electrical-optical conversion efficiency, and high absorption rate.

Compared with fiber lasers commonly used in industrial processing, blue lasers have a 10-60% increase in the absorption rate of metal materials at 450nm, especially for copper, gold and other highly reflective metal materials. The increase in absorption rate is more obvious. It has been verified that the energy consumption required for copper welding is 84% lower than that of infrared lasers, which means that when infrared lasers require 10 W of laser power to weld copper, the use of blue lasers only requires about 1 kW or 0.5kW of power.

3.Dual beam composite welding:

The infrared-visible dual-beam composite welding process is used. Through a lower-power visible laser, the infrared laser can realize forced deep-melt welding of copper when the threshold power of deep-melt welding is lower, and the welding splash is greatly reduced. The equipment cost is low and the welding quality is high. It is considered to have very outstanding advantages and good application prospects.

Aluminum alloy laser swing welding:

When welding aluminum alloys with conventional single-focus laser beams, pores are a common defect. The main reasons for the formation of pores in aluminum alloy are:

1.The welding bath and keyhole vibrate violently and are easy to collapse and stabilize, forming pores;

2.The solubility of hydrogen in aluminum alloy will decrease sharply as the temperature decreases, resulting in the precipitation of supersaturated hydrogen during the solidification process, forming hydrogen pores. The presence of pores can cause stress concentration in the weld, which in turn causes the weld to crack during the solidification process.

Laser swing welding: During the welding process, the beam of light moves along the direction of the weld and swings in various forms such as circular, 8-shaped, and spiral lines at the same time.

At present, the realization of beam swing is mainly achieved through a galvanometer that can withstand high-power lasers. The area of beam action of laser swing welding increases, which increases the area of the keyhole and bath and the size of the root of the bath, improves the stability of the keyhole and bath, and has a significant improvement effect on defects such as poor fusion and biting edges. At the same time, the stirring of the bath by the swinging beam accelerates the convection of the bath, which increases the escape speed of air bubbles in the bath and reduces the porosity.

The current application of laser welding technology in various fields:

Laser is used for welding no later than cutting, and it is used in several fields such as molds, advertising characters, glasses, jewelry, etc., on a very limited scale.In recent years, with the continuous improvement of laser power, more importantly, semiconductor lasers and fiber lasers have gradually developed laser welding application scenarios, breaking the original laser welding technical bottleneck and opening up new market space.

Application of laser welding technology in the field of automobile manufacturing:

In vehicle production, laser welding technology is mainly used in laser welding of thick steel plates, laser assembly welding of automobile assembly and subsystem assembly, laser welding of vehicle parts and other processes. The application of laser welding technology by automobile manufacturers in some countries in Europe and the United States started relatively early. It began in the 1980s. Familiar automobile production brands such as Audi, Mercedes-Benz, and General Motors began to introduce laser welding technology into vehicle manufacturing at that time, which promoted the in-depth application and development of laser welding technology in the field of vehicle manufacturing.

The development trend of laser welding technology:

With the further development and breakthroughs of welding technology, its uniqueness has been even more demonstrated in the research and development process of laser welding technology. Laser welding technology can perform fast and efficient welding of metal materials. At the moment when the laser beam is generated, due to its own high focusing characteristics, it can lead to extremely high power density contained in the laser beam, which allows the laser beam to release a large amount of thermal energy in an extremely short period of time, thereby greatly improving the welding efficiency and ensuring the welding quality.

Due to the instantaneous welding advantages of laser welding technology, it has a very wide range of application prospects. In the practical application process of laser welding technology, when the laser beam directly illuminates the surface of the metal material, it does not affect the surface of the metal material outside the irradiation area, so it does not cause greater damage to the surface of the metal material during the welding process, and after the welding process is completed, there is no need for related surface processing, which makes laser welding technology is particularly suitable for processing the surface of various precision parts, so that more difficult welding operations can also be achieved quickly.

In addition, in the previous welding technical specifications, it is usually stipulated that the material requirements for all welding materials must be the same, and with laser welding technology, there is no need to have great restrictions on the material of the welding material, so even if it is a welding material with different materials, laser welding technology can be used to achieve easy welding. It can be said that the formation and widespread application of laser welding technology have not only effectively overcome the problems in traditional welding technology, but also reduced the difficulty of traditional welding operations.

After more than half a century of development of laser welding technology, its technical level has also become more and more perfect, and it has gradually been widely used in more and more industrial fields.

In the application fields of aerospace, electronic instrumentation, machinery manufacturing, iron and steel metallurgy, automobile manufacturing, medical equipment and other industries, laser welding technology is playing an increasingly huge function. For example, in the production of auto parts, laser welding technology can be used to process and produce the covered parts of the vehicle, and advanced countries such as the United States and Japan have also applied laser welding technology to the production of aviation parts in a pure nitrogen environment.