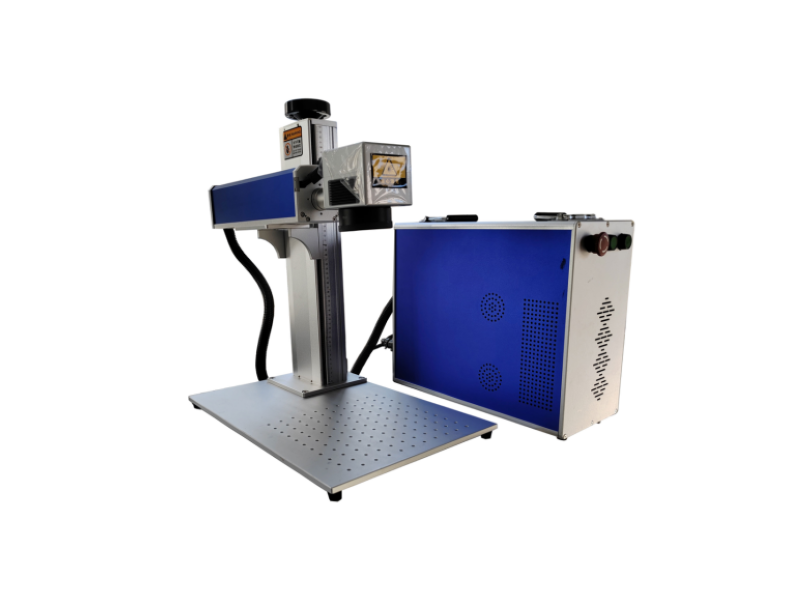

Portable fiber laser marking machine is loved by customers for its friendly operation interface, easy to use, fast marking speed, high efficiency, delicate marking effect, clear, durable and other excellent performance in a working environment with limited space.

However, in the actual operation process, operators often face some problems, resulting in reduced efficiency and even affecting production progress. In order to reduce the number of failures of portable fiber laser marking machine and improve work efficiency, as a portable fiber laser marking machine manufacturer, this article will explain to you three common problems and solutions in the use of fiber laser marking machine.

Why is the pattern of the portable fiber laser marking machine dim?

1. Check temperature and pressure:

The dim pattern of the portable fiber laser marking machine is usually due to the low heating temperature and needs to be adjusted in time. If the molding pressure is very low or the drop is very small, it will also affect the use of the equipment. Therefore, it is recommended to adjust the power and consider whether the temperature stability is guaranteed to ensure that there is no problem with the temperature and pressure, so that the equipment can be used normally. If a similar problem occurs again, the temperature of the fiber laser marking machine should be checked in time.

2. Process control is essential:

Due to the different process controls of the fiber laser marking machine, the patterns presented are also somewhat different. It is recommended to confirm the use process, and the setting, temperature, pressure and material of the molding pressure must be determined. As long as the process can be adjusted and there is no problem with the settings, a good display effect can be guaranteed.

How can the portable fiber laser marking machine improve the marking speed?

1. Internal factors:

The laser frequency, laser spot mode, beam divergence angle and laser power of the fiber laser marking machine will all have an impact on the marking speed. We can adjust the laser beam and spot. The most ideal way is to upgrade the laser.

2. External factors:

Another factor that customers need to pay attention to during the processing of portable fiber laser marking machine is the marking density, marking area and marking depth. Different marking requirements will affect the marking speed.According to these factors, the portable fiber laser marking machine can be reasonably adjusted to appropriately increase the laser marking speed. There may be differences in the adjustment methods of different models of products. You can consult us for after-sales solutions.

Why is the power of the portable fiber laser marking machine attenuated?

1. Fiber loss:

The optical fiber itself has certain losses. As the length of the optical fiber increases, the light energy will gradually be absorbed or scattered, resulting in a decrease in output power. Higher-quality optical fibers can be used and optical fiber losses can be reduced by shortening the length of the optical fiber.

2. Laser aging:

The laser components will gradually age over time, and the laser emission efficiency will decrease, resulting in a decrease in output power.Aging laser components can be maintained and replaced regularly to ensure the performance of the laser.

3. Temperature change:

The lasers are very sensitive to temperature, and changes in ambient temperature may cause the laser's working efficiency to decrease. Too high or too low temperature will affect the laser output power.Try to run the laser within a stable temperature range, and use a cooling system to maintain the operating temperature if necessary.

4. Cooling system failure:

fiber laser marking machine lasers generally require a cooling system to maintain their operating temperature. If the cooling system fails, the laser may reduce its output power due to overheating. The cooling system needs to be checked regularly to ensure its normal operation.

Our Eagle Laser fiber laser marking machine can perform fine marking on various metal and non-metallic materials. And equipped with a reasonable control system design, the use of cache control technology and scanning of selected components, high stability, support long-term continuous production, effectively reduce and avoid the possibility of problems in use.

Our Eagle Laser as a portable fiber laser marking machine manufacturer, provides customers with one-to-one services, quick response, and provides fiber laser marking machine operation videos, manuals, process parameters and other technical information. The most important thing is that we have a customizable courier service. If you have special needs, please contact us for consultation.If you want to know more about other information about fiber laser marking machine, please contact us, we will have more in-depth communication with the technicians, and then share it with you!