Fiber laser cutting machine and CO2 tube laser cuting machine 130W are the two mainstream equipment on the market. However, as industrial manufacturing develops towards high efficiency, energy saving and low maintenance, fiber laser cutting machine has gradually become the new favorite of the industry. Next, we will compare which of the two devices has more advantages in terms of energy efficiency, maintenance cost, cutting speed and material adaptability.

Transmission method: Fiber laser is more flexible.

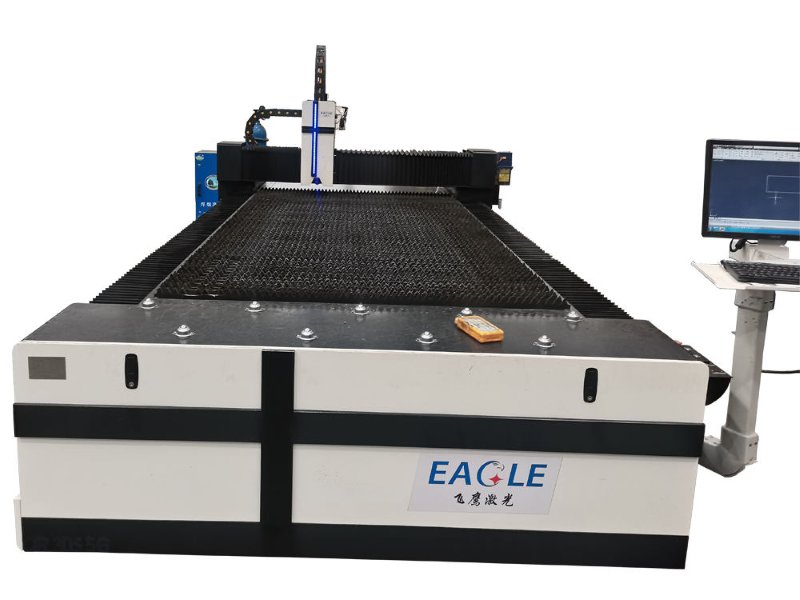

One of the main differences between fiber laser cutting machine and CO2 tube laser cuting machine 130W is the transmission method of laser beam. CO2 laser is transmitted through reflectors, while fiber laser is transmitted directly through optical fiber, which makes the fiber laser system more compact in design and has no space limitation of reflectors, which improves the flexibility and stability of the equipment.

Energy efficiency comparison: Fiber laser cutting machine has obvious advantages.

The electro-optical conversion efficiency of fiber laser cutting machine is significantly higher than that of CO2 tube laser cuting machine 130W , with energy efficiency as high as 25% to 30%, while the actual utilization rate of CO2 laser cutting system is only one-third to one-fifth of it. In addition, the fiber laser cutting machine has an energy efficiency improvement of more than 90% compared with the CO2 system, which means that under the same power consumption, the fiber laser can provide higher cutting efficiency and reduce the energy cost of the enterprise.

Maintenance cost: The fiber laser cutting machine is almost "zero maintenance".

The CO2 tube laser cuting machine 130W requires regular maintenance during use, such as the calibration of the reflector and the inspection of the resonant cavity, while the fiber laser cutting machine basically does not require post-maintenance. This not only reduces maintenance costs, but also reduces downtime and improves the production efficiency of the equipment.

Material adaptability and cutting speed:

Due to the use of short-wavelength laser, the laser cutting machine has a higher absorption rate for non-conductive metal materials (such as brass, copper, etc.) and better cutting effect. In addition, in the cutting process of thin plates and medium and thick plates, the fiber laser cutting machine has higher beam quality and smaller spot, thereby improving cutting accuracy and speed. For example, the cutting speed of a 1.5kW fiber laser cutting system is equivalent to that of a 3kW CO2 laser cutting system, which means that fiber laser can still achieve efficient cutting under low power conditions.

Through the above comparison, we conclude that laser cutting machines are superior to CO2 laser cutting machines in terms of energy efficiency, maintenance costs, cutting speed and material adaptability. For companies that want to improve production efficiency and reduce operating costs, choosing fiber laser cutting machines is actually a more competitive decision. However, this is only in terms of energy efficiency, maintenance costs, cutting speed and material adaptability. Of course, CO2 laser cutting machines also have many other aspects. If you want to know more about the relevant content, you can also leave a message. We will output some related articles for you. Looking forward to your message!