For precision machining, we pay more attention to "control capability":

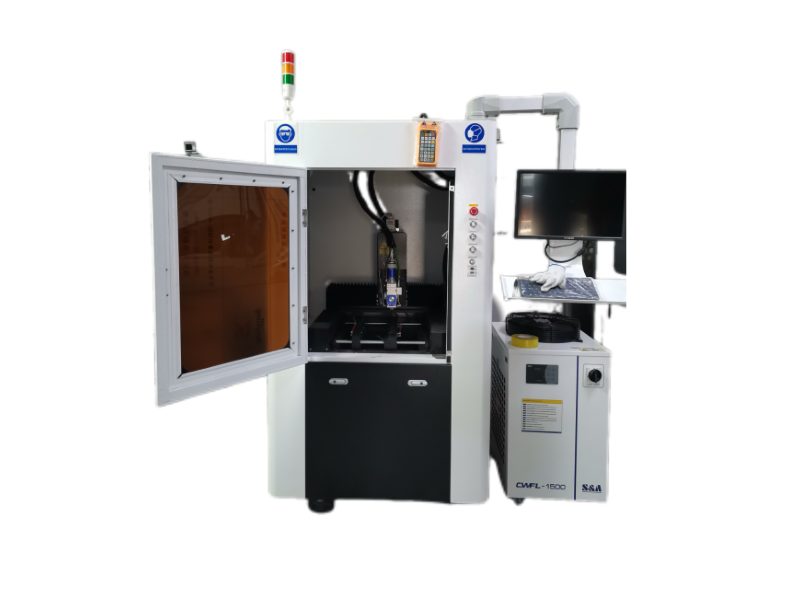

When many customers first contact our 3030 precision fiber laser cutting machine 1500W, they will be attracted by its small processing size, but they often ask questions: "Is it really necessary to equip such a small working platform with a 1500W laser?" From an engineering perspective, this question is reasonable. We use this article to briefly explain some of our ideas when designing this equipment, and also share some usage scenarios and experiences.

1. Controlling small size ≠ reducing performance, but to control variables:

The workbench size of this 3030 precision fiber laser cutting machine 1500W is 300×300mm. The original intention is not to "save costs" or "weaken capabilities", but to serve precision parts processing. In the process of micro-parts processing, whether the control system can achieve accurate positioning and repeated trajectory consistency at high speed is more critical than "cutting fast". We use high-performance linear motor modules, and the closed-loop feedback positioning accuracy is controlled at ±0.03mm, which is crucial for processing fine graphics (such as pinholes/tooth shapes/multi-curved small parts).

2. 1500W laser power is not redundant, but reserves space for efficiency and material range:

We do not intend to let the 3030 precision fiber laser cutting machine 1500W only cut "thin stainless steel" as a single task. With the diversification of user needs, we consider more:

Some customers need to process high-reflective materials such as copper, aluminum, and titanium, which puts forward requirements for the stability and power of the laser light source;

Some medical equipment or structural parts customers require no burrs on the edge and little heat impact. High power + high-speed cutting with appropriate gas parameter settings can bring better cross-section effects;

In small batch processing, unit time efficiency is also a rigid indicator. The 1500W installation allows the equipment to obtain sufficient versatility and efficiency support under the premise of high precision.

3. The core of stable cutting is "follow-up control":

We chose the Raytools BT220 automatic height adjustment cutting head, which has a built-in height detection module, which can keep the focus constant when there is a slight warping on the surface of the material. This is very helpful when processing precision thin plates (especially soft metals), and can effectively avoid problems such as "not cutting through" and "burning edges" caused by focus offset. In our tests, we found that the difference in automatic height adjustment response of different materials (stainless steel, aluminum, copper) will affect the cutting consistency, so we will do special calibration before leaving the factory.

4. About the configuration of the motion system:

The Z axis is equipped with a servo height adjustment mechanism, and the X and Y axes are Panasonic servo motors + precision ball screw structures. With our self-developed drive system, the trajectory stability under long-term operation has been verified in dozens of actual installation cases. Some customers have reported that our accuracy can still be stable within ±0.05mm after continuous processing for more than 3 hours.

In terms of cooling, we use S&A brand chillers to provide dual-circuit temperature control for the laser and cutting head to ensure that there is no drift during long-term work.

5. Our preset application scenarios:

This 3030 precision fiber laser cutting machine 1500W is suitable for cutting tasks of small metal parts that require stability, batch, and high repetitive precision. Most of the customers come from the following directions:

Medical titanium alloy structural parts

Metal brackets and limiters in instruments and meters

Metal shell openings of microelectronic modules

Subsequent cutting of hardware stamping

Research institutions, material college research groups to do experimental cutting of new material microstructures

If you belong to one of the above customers, we recommend giving priority to the 3030 precision fiber laser cutting machine 1500W-not because it "can do everything", but because it is detailed and stable enough in its "scope of application".

We do not think that the 3030 precision fiber laser cutting machine 1500W is a "high-end all-round machine", nor is it designed for general large-format processing. But its performance in the field of precision processing of micro-metal structures is what we, as technicians, are willing to undertake technical commitments-stable control, mature structure, simple debugging, and low maintenance cost, which is what we can do at present.

If you have specific processing questions, please feel free to contact our technical support team at any time. We are willing to verify the most appropriate process parameters together instead of just selling a machine.