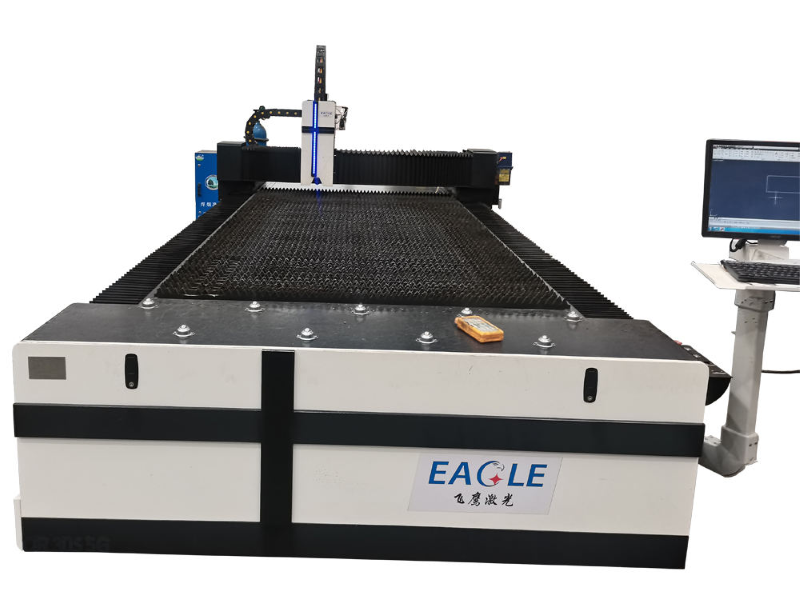

With the rapid development of the manufacturing industry, laser cutting technology has become an indispensable tool in modern industry due to its high precision, high efficiency and contactless processing. As a common device on the market, the 3000W CNC laser steel cutter has been favored by many industries for its powerful cutting ability and wide range of applications. So, how thick can the 3000W CNC laser steel cutter cut? What about its accuracy and speed? This article will give you a detailed answer.

Cutting thickness:

The cutting thickness of the 3000W CNC laser steel cutter is affected by many factors, including laser power, cutting speed, material type, etc. According to actual application data, the cutting thickness range of the 3000W CNC laser steel cutter is as follows:

Carbon steel: 0.5mm-20mm.

Stainless steel: 0.5mm-12mm.

Aluminum alloy: 0.5mm-8mm.

Non-ferrous metals such as copper and brass: 0.5mm-6mm.

Cutting accuracy:

3000W CNC laser steel cutter is known for its high precision, usually achieving an accuracy of ±0.05mm. This is due to its advanced control system and sophisticated optical system. In addition, laser cutting adopts a non-contact processing method, which avoids the influence of mechanical stress on the material, thereby increasing the flatness and accuracy of the cut surface.

Cutting speed:

Cutting speed is an important indicator to measure the efficiency of laser cutting machine. The cutting speed of 3000W CNC laser steel cutter varies according to the type and thickness of the material:

Carbon steel: 10-30 meters per minute.

Stainless steel: 5-20 meters per minute.

Aluminum alloy: 10-25 meters per minute.

Non-ferrous metals such as copper and brass: 5-15 meters per minute.

Advantages:

1.It has relatively low energy consumption while ensuring high cutting efficiency, which is suitable for large-scale production needs.

2.No harmful gases or waste are produced during the laser cutting process, which meets the environmental protection requirements of modern industry.

3. It can cut a variety of materials to meet the diverse needs of different industries.

In addition, our laser cutting machine cutting control software uses the Windows platform and can read files produced by software such as AutoCAD, CorelDraw, and Photoshop. It is more convenient and faster. If you want to know more about our products, please visit our website.

It should be noted that these data are for reference only, and the actual cutting effect also depends on the equipment performance, operating skills and specific characteristics of the material.