What is the difference between fiber laser cutting machine and laser cutting machine? There are many types of laser cutting machines, including CO2 laser cutting machine, YAG metal laser cutting machine, disc laser cutting machine, fiber laser cutting machine, etc.

What is the difference between fiber laser cutting machine and laser cutting machine?

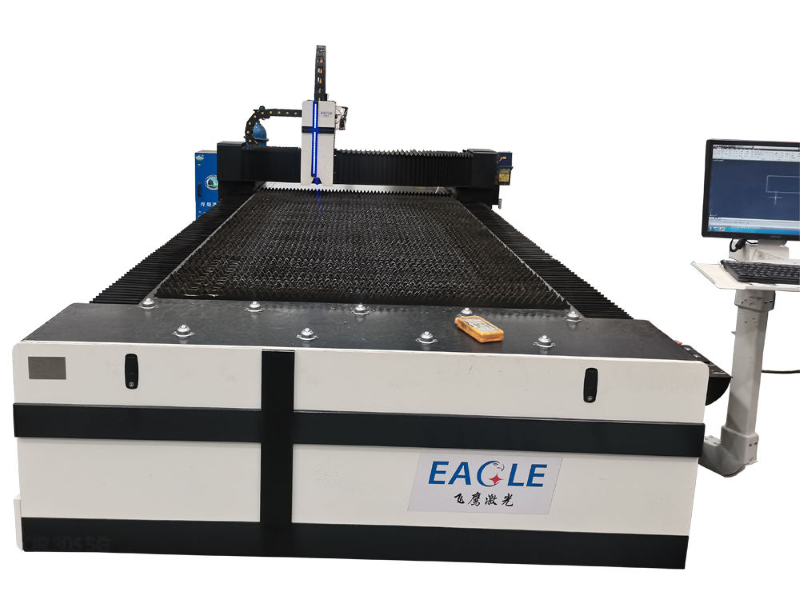

Laser sheet cutting machine is maintenance-free, basically has no consumables, and can cope with harsh working environment, with high tolerance to dust, vibration, impact, humidity and temperature.

CO2 laser cutting machine processing not only produces gas consumption, but also has a photoelectric conversion rate of only 8%~10%. Laser sheet cutting machine does not require any other consumption during processing, and the photoelectric conversion rate reaches 30%, which is more energy-saving and power-saving.

The laser structure of CO2 laser cutting machine is complex, the maintenance cost is high, and the beam divergence is large during processing, which is not suitable for large-format processing. The cutting seam is relatively fine, but the speed is very slow when processing thick plates. The characteristics of Laser sheet cutting machine are miniaturization, intensiveness, high brightness and high conversion rate. In terms of thin plate processing, the cutting speed of Laser sheet cutting machine is 2-3 times higher than that of carbon dioxide with the same power, and the cutting section is smooth.

2. The difference between CNC metal sheet fiber laser cutting machine and YAG laser cutting machine:

CNC metal sheet fiber laser cutting machine not only includes YAG, but also has a higher cutting speed and area, and has a higher cutting quality.

Fiber laser cutting can achieve high power effect with low power, which reduces the cost of cutting and achieves high-quality processing with low energy consumption.

The operation and maintenance are significantly improved.

The main advantages of CNC metal sheet fiber laser cutting machine are its transmission medium and light source; Fiber laser uses diode as light source and optical fiber as transmission medium to transmit lossless light energy to laser cutting head.

3. The difference between CNC metal sheet fiber laser cutting machine and disc laser cutting machine:

a. Technical level: The photoelectric conversion efficiency of fiber laser cutting machine and disc laser cutting machine is about 30%-35%, which is basically the same; the output power range is 0-20KW CW laser output; the beam quality of fiber laser is slightly better than that of disc laser.

b. Application level: In the field of cutting with continuous output laser power below 2000W, fiber laser has obvious advantages.

Application positioning of metal sheet laser cutting machine and other laser cutting machines:

1. Positioning of laser sheet cutting machine: The following cutting, especially the high-precision processing of thin plates, is mainly aimed at manufacturers who require extremely high precision and efficiency. It is estimated that with the emergence of lasers and above, metal sheet laser cutting machine will eventually replace most of the market of CO2 laser cutting machine.

2. Positioning of CO2 laser cutting machine: 6-25 mm medium and thick plate cutting processing, mainly for large and medium-sized enterprises and some pure external processing metal sheet laser cutting machine. The huge impact of the market is in a state of obvious shrinkage.

3. Positioning of YAG metal laser cutting machine: Cutting below 8mm, mainly for self-use small and medium-sized enterprises and most sheet metal manufacturing, home appliance manufacturing, kitchenware manufacturing, decoration, advertising and other industry users with not particularly high processing requirements, gradually replacing traditional processing equipment such as wire cutting, CNC punching, water cutting, low-power plasma, etc.

4. Positioning of disc laser cutting machine: Cutting below 25mm, especially high-quality cutting of medium and thick plates, mainly for external processing, or enterprises processing more non-ferrous metals. The disadvantage is that the later maintenance cost is high, the service and technology have not yet been opened and popularized, and the cost is higher than that of optical fiber. With the emergence of optical fiber 4000W and above lasers, metal sheet laser cutting machine will eventually replace most of the market.