In the fields of industrial manufacturing, electronics, medical care, packaging, etc., laser marking machines have become indispensable precision machining tools. Facing a wide variety of laser marking equipment on the market, how to choose the right model according to material characteristics, processing needs and budget?

The essence of a laser marking machine is to form a permanent mark through a physical or chemical reaction between a high-energy laser beam and the surface of the material. Different types of lasers differ in wavelength, energy density, thermal effects, etc., which determine their applicable materials and processing effects.

Three main lasers:

1. CO2 laser marking machine:

The CO2 laser uses CO₂ gas as the working medium and generates a far-infrared laser through electrical excitation. After the laser beam is expanded and focused, it acts on the surface of the material, and the marking is achieved by gasification or carbonization.

Applicable materials: Wood, paper, leather, fabric, acrylic, plastic (ABS, PP, PE, etc.), rubber, ceramics, glass (surface engraving or coating marking), stone, etc.

Advantages: The processing effect of non-metallic materials is good, the speed is fast, and the equipment cost is relatively low.

Disadvantages: The marking effect of pure metals and some hard plastics (such as untreated PC) is poor, and the heat-affected area is relatively large.

Typical applications: Food packaging date batch number, wood product engraving, acrylic signage, leather product marking, glass glass engraving.

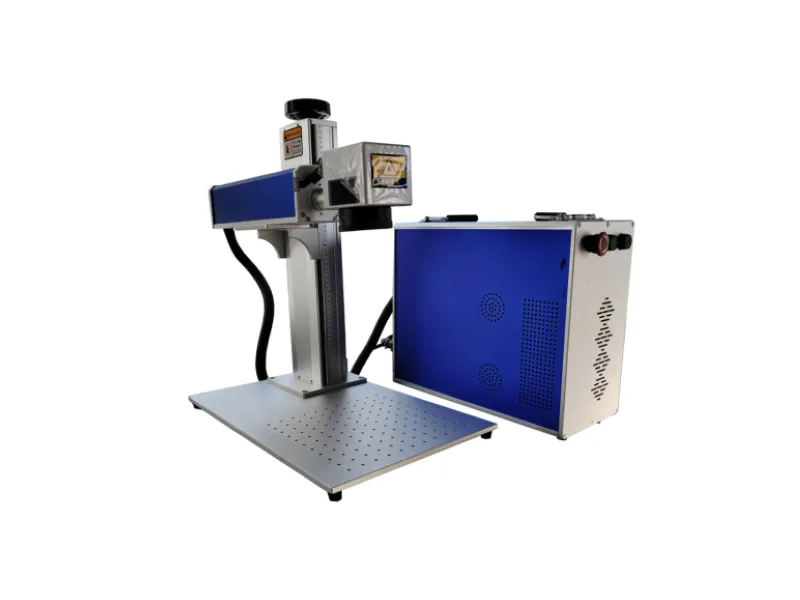

2. Fiber laser marking machine:

Fiber lasers use optical fibers doped with rare earth elements as the gain medium to output near-infrared lasers. The laser path is controlled by a high-speed galvanometer system, and a mark is formed on the surface of the material by evaporation or oxidation.

Applicable materials: Stainless steel, aluminum, copper, iron, titanium alloy, coated metal and other metal materials, epoxy resin, ABS plastic, ink coating and other non-metallic materials.

Advantages: The beam quality is excellent, the focusing spot is small, the accuracy is high, the marking speed is fast, the metal marking effect is excellent, the electro-optical conversion efficiency is high, maintenance-free (no consumables), and the service life is long.

Disadvantages: It has poor effect or cannot be marked on most pure non-metallic materials (such as wood, uncoated glass, and ordinary plastics).

Typical applications: Hardware tool nameplates, electronic product metal housings, auto parts traceability codes, medical device marks, tool marks.

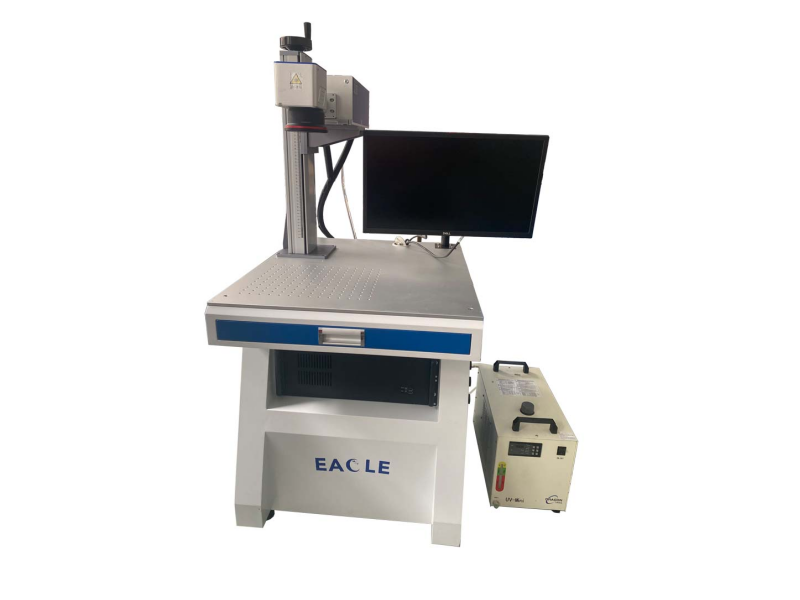

3. Ultraviolet laser marking machine:

The ultraviolet laser generates an ultraviolet laser through the third-order cavity frequency doubling technology, and uses the “photoreceptor” effect to interrupt the molecular chain of the material to achieve cold processing (no significant heat-affected zone).

Applicable materials: PCB circuit boards, silicon wafers, glass, sapphire, ceramics, electronic components (IC chips, sensors), medical devices (scalpels, catheters) and other high-precision demand scenarios.

Advantages: The characteristics of ”cold processing", the heat-affected zone is very small, ultra-fine marking (micron level) can be achieved, the surface damage to the material is small, and high-contrast marking can be obtained on most materials.

Disadvantages: Equipment costs and maintenance costs are relatively high, and the processing speed is usually slower than that of optical fiber.

Typical applications: Electronic components, fine QR codes, mobile phone buttons/housings, pharmaceutical packaging, food packaging plastic film, glass art, FPC/PCB board marking.

Eagle Laser marking machine series-provides optical fiber, CO₂, ultraviolet and other types of laser marking equipment, suitable for metal, plastic, ceramics, glass and other materials, widely used in electronics, hardware, medical equipment, packaging and other industries, to help enterprises achieve product identification traceability, anti-counterfeiting and personalized customization, accurate and efficient, and enable intelligent manufacturing!