Overview of laser processing equipment manufacturing industry:

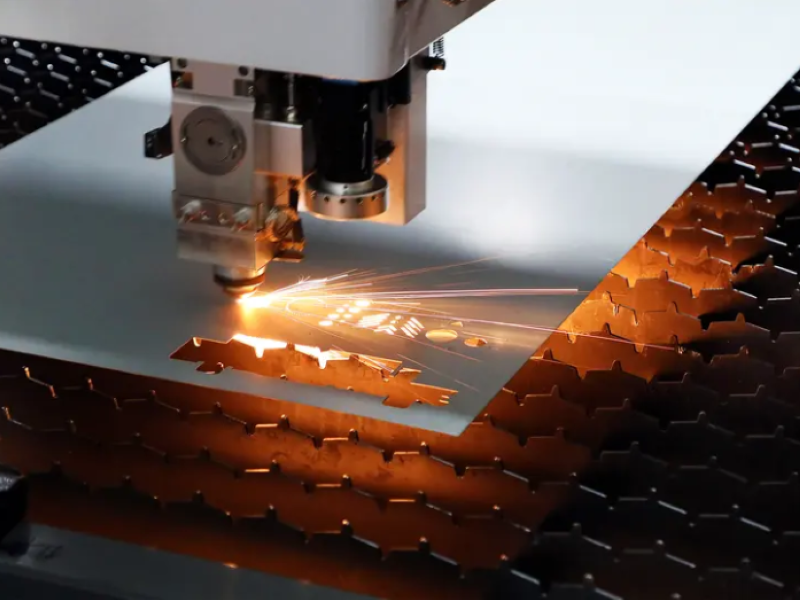

Laser processing is an industrial application of laser technology. It focuses a certain power of laser on the object to be processed, so that the laser interacts with the object, heats, melts or vaporizes the processed material to achieve the processing purpose. Laser processing is a typical non-contact processing. Compared with other processing methods, it has significant advantages such as fewer subsequent processes, good controllability, easy integration, high processing efficiency, low material loss, low environmental pollution, high flexibility and high quality. Laser processing equipment is a high-tech product that integrates a variety of high-tech technologies. It exists in almost all industrial sectors and reflects a country's production and processing capabilities, equipment level and competitiveness. Therefore, the laser processing equipment manufacturing industry is one of the industries that various countries pay the most attention to and develop the fastest. According to the nature of the laser, laser processing equipment can be divided into gas lasers, solid lasers, semiconductor lasers, liquid lasers, chemical lasers, free electron lasers, etc.; according to different functions, it can be divided into laser welding machines, laser engraving machines, laser cutting machines, laser marking machines, etc.

Laser processing equipment manufacturing industry policy:

In recent years, China's laser processing equipment manufacturing industry has received high attention from governments at all levels and key support from national industrial policies. The country has successively introduced a number of policies to encourage the development and innovation of the laser processing equipment industry. For example, in June 2023, the Ministry of Industry and Information Technology and other five departments issued the "Implementation Opinions on Improving the Reliability of the Manufacturing Industry", proposing to focus on improving the reliability of industrial mother machines such as vertical/horizontal machining centers, five-axis linkage machining centers, turning and milling composite machining centers, heavy CNC machine tools, large die-casting machines, hydraulic/servo presses, laser welding and cutting equipment, vacuum heat treatment furnaces, additive manufacturing, large high-end intelligent agricultural machinery, small and suitable agricultural machinery in hilly and mountainous areas, and other agricultural machinery equipment, industrial robots and other products. In January 2024, the Ministry of Industry and Information Technology and other seven departments issued the "Implementation Opinions on Promoting the Innovation and Development of Future Industries", proposing to develop intelligent manufacturing, biomanufacturing, nanomanufacturing, laser manufacturing, and circular manufacturing, break through key core technologies such as intelligent control, intelligent sensing, and simulation, promote flexible manufacturing, shared manufacturing and other models, and promote the development of industrial Internet and industrial metaverse.

Time Department Policy Name Related Content:

May 2022 MIIT and other 11 departments "Notice on Carrying out the "Hand in Hand Action" to Promote the Integration and Innovation of Large, Medium and Small Enterprises (2022-2025)" Driven by digitalization, promote collaborative innovation and technological transformation of large, medium and small enterprises, and enhance the technological transformation capabilities of small and medium-sized enterprises.

June 2022 MIIT and other six departments "Industrial Energy Efficiency Improvement Action Plan" Promote energy-saving and efficiency-enhancing transformation in key industries, and develop green manufacturing processes such as laser heat treatment and laser cleaning.

January 2023 Xinxiang Municipal People's Government "Xinxiang's 14th Five-Year Plan for Science and Technology Innovation and First-Class Innovation Ecosystem Construction Plan" Carry out the construction of industrial chains such as laser processing islands, intelligent manufacturing, laser processing and 3D printing equipment, and support the innovative development of the intelligent equipment industry.

June 2023 MIIT and other five departments "Implementation Opinions on Improving Reliability in Manufacturing" Improve product reliability and promote the improvement of key reliability technologies such as laser welding, laser heat treatment, and composite laser additive manufacturing.

January 2024 Henan Provincial People's Government "Henan Province Major Technical Equipment Research Plan (2023-2025)" Breakthrough the core technologies of high-end equipment such as laser cutting machine tools and laser radars, and promote the independent control of high-end equipment.

January 2024 Ministry of Industry and Information Technology and other seven departments "Implementation Opinions on Promoting the Innovation and Development of Future Industries" Focus on future industries such as laser manufacturing and bionic manufacturing, promote the integrated development of intelligent manufacturing and future industries, and build a high-end equipment industry ecosystem.

| Date | Department | Policy Name | Related Content |

| May 2022 | MIIT and 10 other departments | Notice on Carrying Out the 'Joint Action' to Promote Collaborative Innovation Among Large, Medium, and Small Enterprises (2022–2025) | Driven by digitalization, promote collaborative innovation and technological transformation among enterprises of all sizes, and improve the technological transformation capabilities of SMEs. |

| June 2022 | MIIT and 5 other departments | Industrial Energy Efficiency Improvement Action Plan | Promote energy-saving and efficiency-enhancing transformations in key industries, and develop green manufacturing processes such as laser heat treatment and laser cleaning. |

| January 2023 | Xinxiang Municipal Government | Xinxiang City's 14th Five-Year Plan for Scientific and Technological Innovation and First-Class Innovation Ecosystem Construction | Develop industrial chains including laser processing islands, intelligent manufacturing, laser processing and 3D printing equipment, and support the innovation and development of the intelligent equipment industry. |

| June 2023 | MIIT and 4 other departments | Implementation Opinions on Improving Manufacturing Reliability | Improve product reliability and promote key reliability technologies such as laser welding, laser heat treatment, and composite laser additive manufacturing. |

| January 2024 | Henan Provincial Government | Henan Province Major Technical Equipment Tackling Plan (2023–2025) | Break through core technologies of high-end equipment such as laser cutting machines and LiDAR, and promote independent controllability of high-end equipment. |

| January 2024 | MIIT and 6 other departments | Implementation Opinions on Promoting the Innovation and Development of Future Industries | Focus on future industries such as laser manufacturing and bionic manufacturing, promote the integration of intelligent manufacturing with future industries, and build a high-end equipment industry ecosystem. |

Laser processing equipment manufacturing industry industrial chain:

The upstream of the laser processing equipment manufacturing industry industrial chain is the supply link of materials and parts, mainly including optical materials, optical devices, CNC systems, electrical devices, etc. Among them, optical materials include crystal materials, special optical fibers, etc.; optical devices include lasers, fiber amplifiers, etc.; CNC systems include servo motors, main control boards, etc.; electrical devices include continuous power supplies, pulse power supplies, etc. The midstream is the production and supply link of laser processing equipment, mainly including welding equipment, cutting equipment, marking equipment, engraving equipment, etc. Downstream is widely used in automobile, machinery, electronics, printing, medical, photovoltaic, lithium battery, military, semiconductor, aerospace and other fields.

Laser is the heart of laser processing equipment. The performance of laser directly affects the quality and use effect of laser processing equipment, especially in the field of ultra-precision processing. Thanks to favorable policies, as well as the growing demand for lasers in smart devices, consumer electronics, new energy and other fields, and the continuous expansion of emerging application fields such as medical and beauty equipment, the scale of my country's laser market has maintained steady growth. According to statistics, the scale of my country's laser market has increased from 70.2 billion yuan in 2019 to 121 billion yuan in 2023, with an annual compound growth rate of 14.58%. It is estimated that the market scale of China's fiber laser industry will reach 145.5 billion yuan in 2024. In the future, with the rapid growth of applications such as automation, intelligent manufacturing and new energy, more emerging companies will enter the laser market, driving the growth of the industry market scale.

As one of the downstream application fields of the laser processing equipment manufacturing industry, the automotive industry has a huge industrial scale and high requirements for precision manufacturing, which provides a broad application space for laser processing technology. In the process of automobile manufacturing, laser processing technology is widely used in key process links such as body welding, surface treatment, and parts cutting. Especially in the context of the rapid development of new energy vehicles, laser processing has shown unique advantages in emerging fields such as power battery welding and lightweight material processing. According to data from the China Association of Automobile Manufacturers, China's automobile industry production and sales increased year by year from 2015 to 2017. Since 2018, my country's automobile industry has faced great pressure due to the full withdrawal of the purchase tax preferential policy and the decline in macroeconomic growth. In particular, the sudden outbreak of the epidemic in 2020 further aggravated the difficulties of the automobile industry, resulting in pressure on both ends of automobile production and sales, and the industrial chain and supply chain were severely impacted. Production and sales fell to 25.225 million and 25.311 million vehicles respectively. Since 2021, problems such as insufficient supply of chips and high prices of raw materials on the supply side have gradually improved, and China's automobile production and sales have begun to resume growth. In 2024, China's automobile production and sales will reach 31.282 million and 31.436 million respectively, an increase of 3.7% and 4.5% year-on-year respectively. In January 2025, China's automobile production and sales reached 2.45 million and 2.423 million respectively, with a year-on-year increase of 1.7% in production and a year-on-year decrease of 0.6% in sales. With the continuous growth of automobile production and sales, higher requirements are put forward for the accuracy, efficiency and reliability of the laser processing equipment manufacturing industry, which further promotes the innovative development of laser processing technology.

In the next article, we will continue to talk about the development status of the laser processing equipment manufacturing industry, so stay tuned!