FAQ 1: Complex operation is prone to errors:

According to our experience, novice users usually have poor marking effect or material waste due to the complex adjustment of the parameters of the portable fiber laser marking machine.

Detailed answers and operation suggestions:

The root cause of the problem lies in the unintuitive software interface or environmental factors.

Please follow the steps:

Initial Settings: After confirming that the connection is stable, the portable fiber laser marking machine uses software automatic calibration functions (such as EZCAD) to reduce human error.

Parameter optimization: For metal or plastic materials, the power is adjusted from 20W, the frequency is set to 50-100kHz, and the speed is controlled at 500-1000mm/s.

Suggestions: Use preset templates and backup parameters regularly.

Anti-Error Tips: First test on the sample in a small range; if blurred, adjust the focal length (5-10cm). This portable fiber laser marking machine has built-in guidance to avoid common mistakes.

FAQ 2: Maintenance costs are high and environmentally difficult to adapt

Customers often require frequent maintenance in high temperature or dusty environments, resulting in downtime and additional expenses.

Detailed answers and operation suggestions:

Environmental factors can easily affect core components.

Adopt the following strategies:

Daily Maintenance: Clean the fiber heads every week (with a dust-free cloth) and monitor the coolant level to prevent overheating.

Environmental control: Use IP54 protective cover in dust areas to avoid humid environments. Tip: Change the filter every quarter to optimize the performance of portable fiber laser marking machine.

Cost control: Quarterly preventive inspections can reduce maintenance costs by 50%.

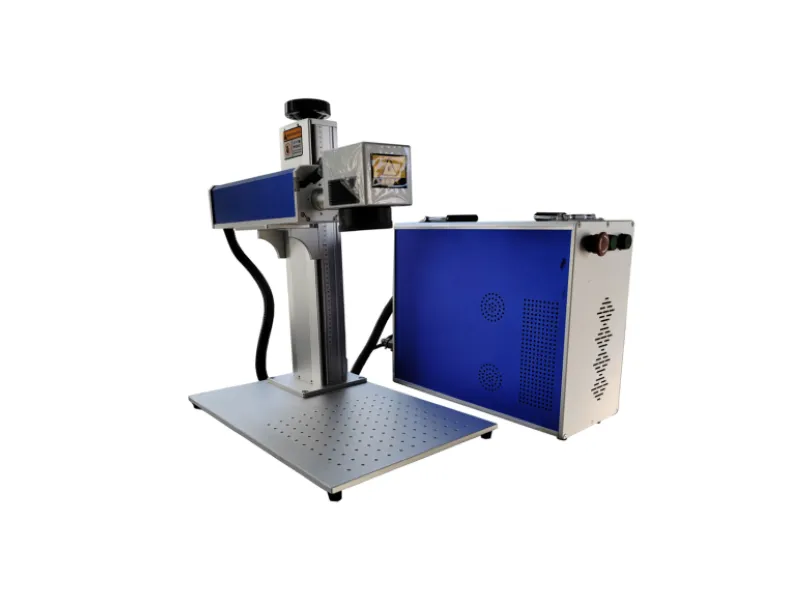

Eagle Laser is located in the Optoelectronics and Intelligent Manufacturing Equipment Industrial Park in Changchun, Jilin. China's first laser was manufactured in Changchun. Relying on the Changchun Institute of Optics, Precision Mechanics and Physics (ClOMP), Jilin University, and Changchun University of Science and Technology (CUST), it is a high-tech manufacturing enterprise. Adhering to the model of customer satisfaction, employee happiness, and value creation, it is committed to creating a high-end brand service business philosophy in the laser equipment industry. We focus on the design and production of professional laser equipment such as laser cutting, marking, welding, rust removal, and obstacle removal. Eagle has dozens of products with technical advantages of high electro-optical conversion rate, high reverse resistance, customized output fiber length, and high beam quality. We have won the trust and praise of users at home and abroad. Choose our 20W portable fiber laser marking machine and enjoy excellent performance and our manufacturer-level service. Visit the official website now to learn more, or contact customer service to make an appointment for a free demonstration!