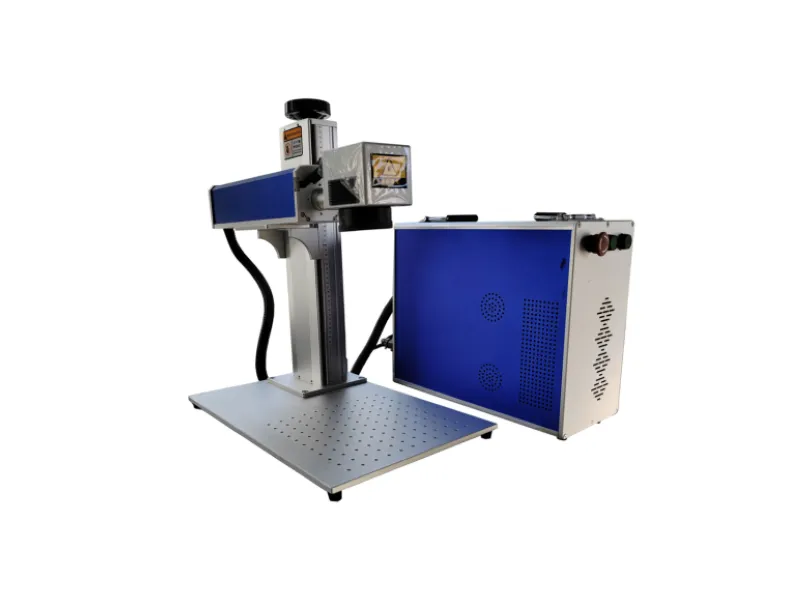

This 20W split fiber laser marking machine is produced in Jilin, China. Under normal circumstances, the delivery time is 10 days (in case of special needs, it can be negotiated and adjusted). The split-type fiber laser marking machine adopts a split-type design, which is compact in structure, portable and easy to install, and is suitable for working environments with limited space. The photoelectric conversion efficiency is high, which can significantly reduce energy consumption and operating costs; at the same time, it is equipped with intelligent software, friendly operation interface, fast marking speed and high accuracy (working accuracy 0.0123mm), and supports marking of various materials.

This split fiber laser marking machine manufactured by Changchun Eagle Laser Equipment Co., Ltd. adopts an innovative split design, has extremely high photoelectric conversion efficiency, and can significantly reduce energy consumption. It has a compact structure, which is particularly suitable for working environments with limited space, and the delivery cycle takes only 10 days. The following are integrated answers to common customer questions:

Core points of safe operation:

Before operating the split fiber laser marking machine, please remember to wear laser protective glasses and gloves to ensure that the work area is well ventilated and away from flammable substances. Check the stability of the power supply connection before each power-on to confirm that the air-cooled system is not clogged. This split fiber laser marking machine adopts an intelligent protection mechanism. If you encounter abnormal conditions such as overheating of the equipment, please immediately power off and contact our 24-hour after-sales team.

Efficient operation of the whole process:

The split fiber laser marking machine supports multi-size marking areas from 110×110mm to 300×300mm.

During operation:

30 seconds after connecting the power supply, the system self-test is completed.

Install smart marking software via USB (compatible with AI/DXF and other formats).

Setting parameters: 18-20W power is recommended for metal materials, 10-15W for non-metals

After fixing the workpiece, click start, and the it will automatically perform high-precision marking.

At the end of the operation, press the software stop button → shut down → clean the lens

Maintenance and troubleshooting:

When we design our products, in order to maintain the best performance of the split fiber laser marking machine: it is recommended that you clean the lens and air vents with a dust-free cloth every week; check the line connection every month; continuous operation does not exceed 8 hours.In case of blurred marking, please check the material compatibility (this split fiber laser marking machine supports metal/non-metal), adjust the scanning speed parameters; suspend use when the equipment overheats and check the air-cooled system.All operation videos can be obtained through our one-to-one service.

Exclusive service guarantee:

We provide process parameter manuals and operation videos for each it, which significantly reduces the difficulty of new employee training. Global delivery through DHL/TNT/FEDEX, standard 10-day delivery, special needs can be customized. Welcome to contact our professional technical team through the website or email to obtain in-depth technical support for it.