The hardware accessories produced on the assembly line have always occupied a large share of our country's market. Especially in recent years, China's foreign trade has gradually expanded, leading to a rapid increase in demand for hardware accessories. At the same time, our country is a large manufacturing country, and manufacturing technology has developed rapidly. However, laser marking machines are more and more widely used in hardware accessories. Today, Eagle Laser will share with you the marking process of laser marking technology on hardware accessories.

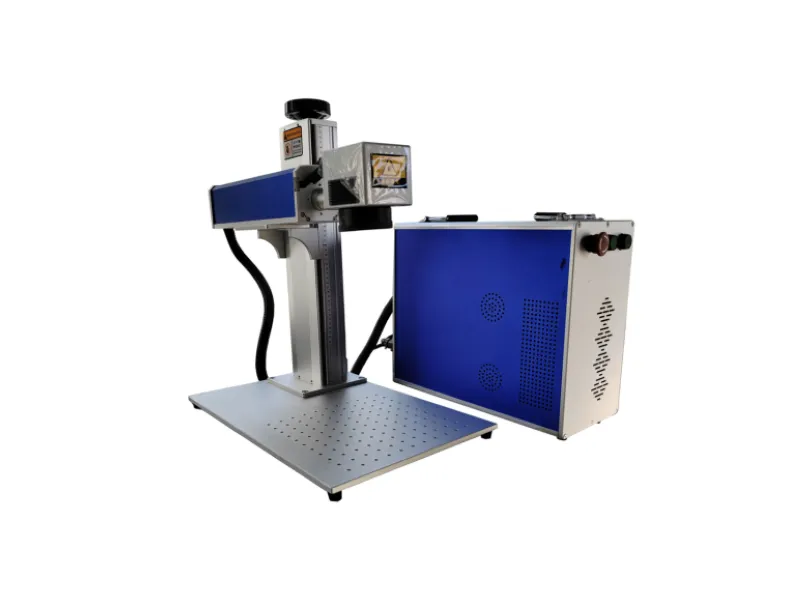

Generally speaking, the various marking methods of hardware accessories have their own marking characteristics and the range of materials suitable for marking. The excellent performance and quality of split fiber laser marking machine continue to expand its influence in the production process of hardware accessories. Our split fiber laser marking machine has high electro-optical conversion efficiency, small size, good output beam quality, high reliability, and long operating life. It can meet the requirements of marking a large amount of data we want on top of very small hardware accessories. .

In addition, our split fiber laser marking machine can also mark various text, serial numbers, product numbers, barcodes, QR codes, production dates, etc. on hardware accessories. The text and graphics after laser marking with our split fiber laser marking machine are not only clear and delicate, but also cannot be erased or modified, which is very beneficial to product quality and channel tracking, and can effectively prevent the sale of expired products and anti-counterfeiting.

The hardware accessories carved with our split fiber laser marking machine have fine patterns, with a working accuracy of up to 0.0123mm, and the nicks are durable, beautiful and clear. Our split fiber laser marking machine has better functional advantages than traditional embossing or jet marking methods.

In the production process, manufacturers generally choose the appropriate marking method according to specific production needs when choosing. However, our split fiber laser marking machine is easy to install, even for large-scale and complex assembly lines, it can ensure that production runs freely. Not only that, our Eagle Laser supports customized services, and manufacturers can customize laser marking machines suitable for their own products according to their needs. At the same time, our split fiber laser marking machine can not only meet the different production needs of hardware accessories, but also its performance is stable and reliable. It can meet the production needs of manufacturers in all directions, thereby expanding the scope of application of laser marking machines.

As a high-tech enterprise focusing on the research and development and manufacturing of laser equipment, Eagle Laser, the split fiber laser marking machine we produce has become a good choice for marking in the hardware industry with its good performance and wide applicability. The split fiber laser marking machine produced by Eagle Laser has brought huge changes to the hardware industry with its excellent performance and wide range of applications. It not only improves production efficiency, reduces production costs, but also improves product quality and market competitiveness. In the future development, our Eagle Laser will continue to be committed to the innovation and progress of laser technology, provide better marking equipment and services for the hardware industry, and help the hardware industry prosper and develop.