Today we will introduce our most popular machine: Fiber laser continuous platform welding machine.

Let me first briefly introduce the machine: Fiber laser continuous platform welding machine, which uses a new generation of fiber laser light source, is equipped with a single pendulum or double pendulum welding head, and has the advantages of simple operation, beautiful and undamaged welds, fast welding speed, high efficiency, no consumables and no pollution. Welding of metal materials such as stainless steel plates, iron plates, galvanized plates, etc. Achieves high-quality results.

Fiber laser continuous platform welding machine composition structure:

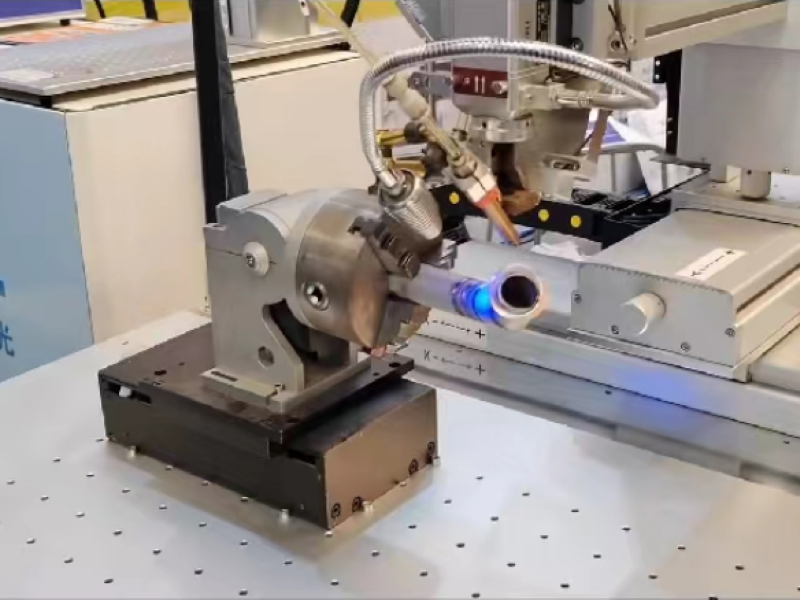

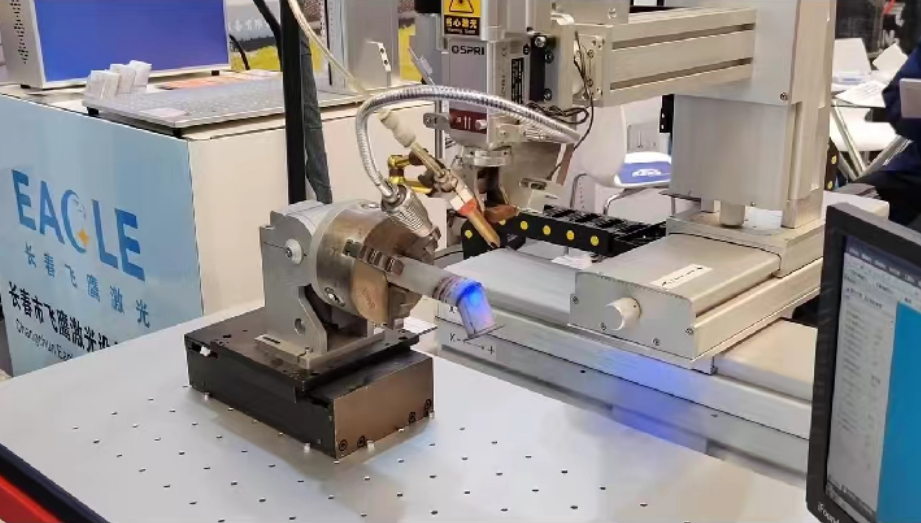

Fiber laser continuous platform welding machine is equipped with a standard separated x/y/z axis three-dimensional automatic moving workbench. A rotating fixture can also be selected to achieve two-dimensional fully automatic laser welding. The monitoring system uses a microscope and red light, and is equipped with an external water cooling system.

1. Laser system: Laser light source, laser power supply, laser control card, welding head, optical path and other main parts.

2. Cooling system: Because the laser welding machine operates at high power and generates high-energy heat when working, the cooling system can cool the laser. The power of the chiller equipped with different powers is different.

3. Workbench cabinet: The workbench is a metal table, and the table space can include a bracket for placing the display and measuring instruments; it is small in size, and the table layout can be customized according to user requirements, such as installing manual lifting accessories, etc. The workbench refers to the laser welding automatic workbench, or also called the motion system. The workbench makes the laser beam move according to specific requirements and welding trajectories, thereby realizing the automatic welding function of the laser. It can be said that the workbench is the core component of the laser continuous platform welding machine, which mainly controls the welding action. Relatively speaking, the motion control of the workbench is to write the motion through CNC programming, so as to control the program and make the workbench move as required.

4. Screen observation system: The machine is equipped with a screen observation and detection system, which can observe and detect the welding effect of the laser welding spot and weld at any time, the trajectory that has been run, etc.

5. Install the automation equipment system:laser continuous platform welding machine can cooperate with three-axis, four-axis linkage worktable, manipulator, cantilever worktable to realize precision welding motion trajectory control, and can choose different working trajectory ranges.

6. Servo wire feeder can be selected for welding workpieces with large gaps. The wire feeder feeds wire smoothly, and with the welding head, it can achieve perfect welding of precision workpieces with large welds.

Welcome everyone to buy our Eagle products, and look forward to your contact!