During the processing of the laser sheet cutting machine, everyone will encounter many problems. For example, the common non-penetration problem during the processing is very troublesome. So why does the equipment have such a problem? Today we will take stock of it.

1. Why does the laser power decrease?

The core component of the laser sheet cutting machine, the laser, will gradually reduce its power after long-term use. The power attenuation of the laser sheet cutting machine is mainly due to factors such as aging of optical devices and laser cavity pollution, which leads to a decrease in output power, thereby affecting the cutting effect.

2. Does the thickness of the sheet exceed the limit of the equipment?

Laser sheet cutting machines of different powers have their limit cutting thickness. If the processed sheet exceeds the cutting capacity of the equipment, it is difficult to achieve complete cutting even if other parameters are adjusted. Therefore, when selecting equipment, it is necessary to fully consider the actual processing needs.

3. Are the optical components contaminated?

Optical components (such as focusing mirrors, reflectors, etc.) are prone to accumulate dust and residues in harsh environments, which will directly affect the transmittance of the laser and cause energy loss. If the optical components are seriously contaminated, the laser beam may not be able to achieve the expected cutting ability, resulting in non-penetration.

4. Is the spot adjustment of the equipment up to standard?

The quality of the spot directly affects the cutting accuracy and penetration ability. If the spot of the laser sheet cutting machine is not adjusted in place, the focus is offset or not focused, it will affect the energy density of the laser, resulting in incomplete cutting. 、

5. Is the cutting speed too fast?

In some cases, in order to improve production efficiency, the operator may adjust the cutting speed. However, if the cutting speed is too fast, the laser beam may not have enough time to penetrate the material, resulting in missed cutting or incomplete cutting. Therefore, in the processing of different materials and thicknesses, the cutting speed needs to be adjusted reasonably.

6. Is the auxiliary gas pressure sufficient?

Auxiliary gases (such as oxygen, nitrogen, etc.) help blow away slag during cutting and improve cutting quality. If the gas pressure is insufficient, slag May remain in the cutting seam, resulting in non-penetration. Therefore, when using the laser sheet cutting machine, the auxiliary gas pressure needs to be within a reasonable range.

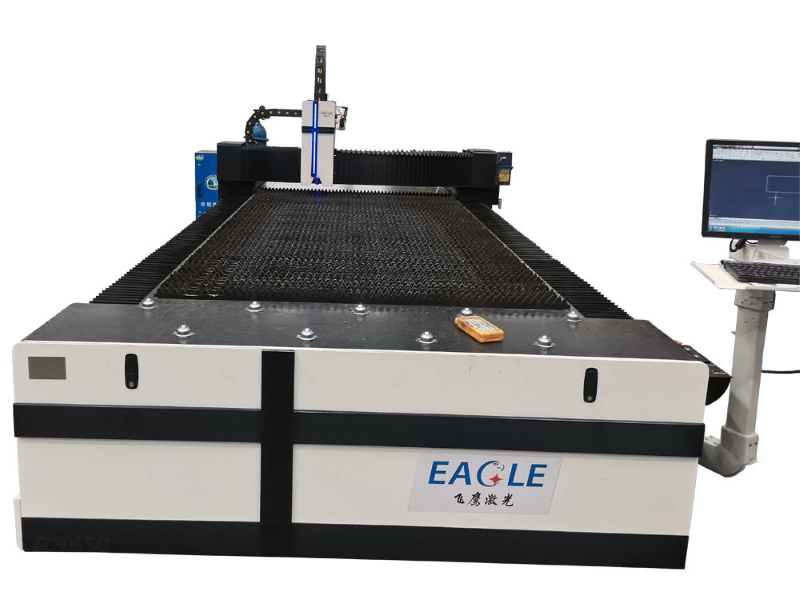

Eagle is a high-tech enterprise focusing on the research and development, production and sales of laser application equipment, located in Changchun, Jilin. The company's products cover four categories, including laser cutting machines, laser marking machines, laser welding machines, and laser cleaning machines, which are exported to more than 100 countries and regions including Europe, America, Japan, and South Korea. It is widely used in automotive sheet metal, chassis cabinets, storage equipment, metal products, advertising decoration, engineering machinery, agricultural machinery, fitness equipment, elevator accessories, medical equipment, electrical appliances and kitchenware and other industries.

Faced with the difficulties in using laser cutting machines, we always adhere to technological innovation, continuously optimize product performance, and help users improve production efficiency. If you encounter problems during use, please contact us and we will provide you with professional technical support.

Have you encountered similar cutting problems? You may try to optimize according to the above method, or contact professional manufacturers to get a more accurate solution!