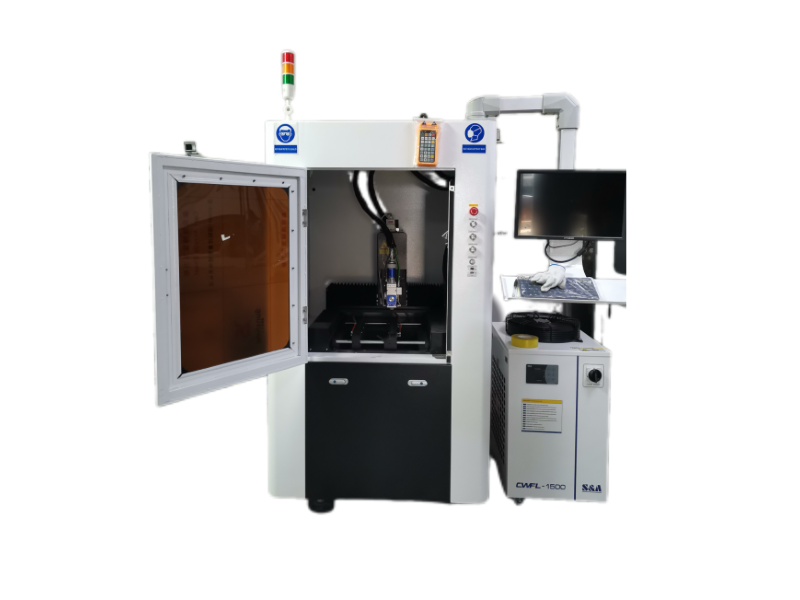

If it is a machine, there will be loss, and the metal material small enclosed fiber laser cutting machine is the same. In the long-term development and use process, we will definitely affect the existence of some more or less loss, such as slow cutting speed, poor cutting processing accuracy and other problems. Many people may think that the laser power must have decreased. In fact, there are many reasons that affect the power reduction of the small enclosed fiber laser cutting machine, not necessarily a laser problem. The following analyzes the reasons for the power failure of the small enclosed fiber laser cutting machine:

First, it is a focal position. The focal position affects the cutting accuracy, especially the focal spot diameter. The focal spot diameter is proportional to the focal depth of the focusing lens. The smaller the focal depth of the focusing lens, the smaller the focal spot diameter.

The second is the distance through the nozzle. The distance between the workpiece and the nozzle also affects the research of the fiber laser cutting machine power capacity. Being too far away will cause unnecessary kinetic energy waste, and being too close will affect the dispersion of the splashing cutting products. The appropriate distance is 0.8mm. Anothersmall enclosed fiber laser cutting machine mainly relies on its follow-up adjustment to cut uneven workpieces. During the operation and management process, the height of the nozzle and the workpiece should not be kept basically consistent.

Third, the cutting speed and cutting speed have a great influence on the power of the fiber laser cutting machine, and the cutting speed is proportional to the power of the fiber laser cutting machine. At the same time, the quality of cutting work is related to the quality management of the laser beam, and it is also related to the characteristics of the laser beam focusing information system, that is, the size of the laser beam after focusing has a great impact on the quality of laser cutting.

There are also the size of the auxiliary gas, the auxiliary gas and the gas pressure. It is preferred to use compressed air or inert gas, which also affects the power of the fiber laser cutting machine. If the thickness of the processed material can be increased or the cutting speed is slow, the gas pressure should be appropriately reduced. Cutting with less efficient gas pressure can prevent frosting of the cutting edge.

Finally, the laser power, if the first 4 have been excluded, is considered to be a decrease in laser power. Any equipment will cause problems after long-term use, and some parts will age. Laser is the core and most important component of metal laser cutting machine. Long-term use will lead to power decline. In addition to the above points, the performance, size and thickness of the processing technology materials will also affect the power capacity decline of the fiber laser cutting machine.

The above are the reasons that may cause the small enclosed fiber laser cutting machine to decline during the use of the laser cutting machine. As long as you find the right method, you can solve it. Have you learned it?

The above content is for reference only, and please handle it according to the equipment itself.