Why is the laser welding machine not firmly welded during welding? Is there a problem with the laser welding equipment? When the laser welding machine is welding, the welding between the materials is not firm, which will affect the overall quality. At this time, it is understandable that users will inevitably question the effect of the laser welding machine. There are many reasons for the instability of laser welding. During the welding process, the laser welding machine is affected by the welding materials, welding environment, welding process, etc., which will affect the welding effect.

Why is the laser welding machine not firmly welded?

1. Contamination of the surface of the material

Generally speaking, when using the laser welding machine for welding, pay attention to whether there is dirt on the surface of the material. If the material with dirt is placed in the welding area, the surface of the material will not be able to crystallize normally or the crystallization will be insufficient, which is one of the factors that directly affect the instability of the laser welding machine;

Solution:

Strict cleaning should be carried out before welding. Organic solvents such as anhydrous alcohol and acetone can be used to remove oil stains, and rust spots or oxide scales can be polished or laser cleaned. For high-reflective materials, surface roughening treatment (such as sandblasting) can also be performed to improve the absorption rate. Keep the material dry and avoid the influence of humid environment on welding.

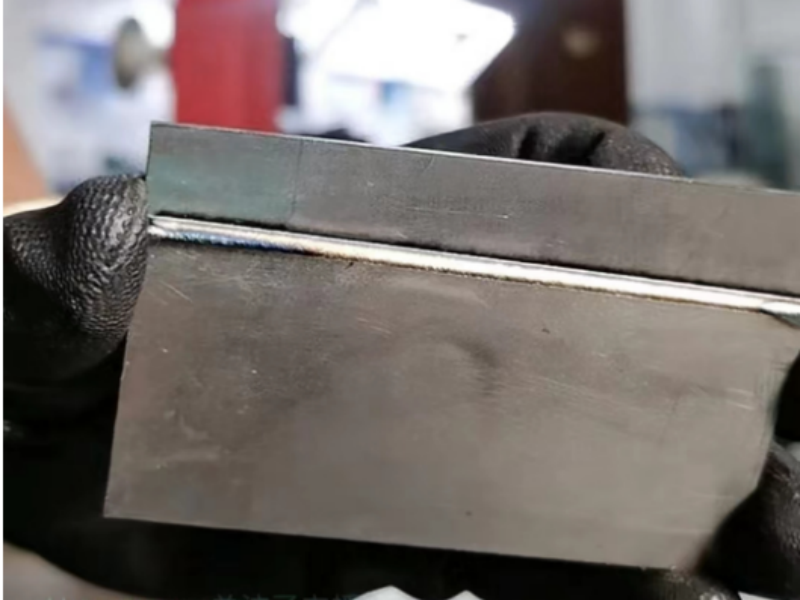

Post-weld characteristics:

The surface is black or dark, the weld edge is blurred, often accompanied by pores, spatter or cold welding, the welding is not tight, and the mechanical properties are poor.

2. The welding speed is too fast:

When using the laser welding machine, users often mistakenly believe that the faster the welding speed, the faster the production and the better the product. In fact, when the laser welding machine acts on the material processing, the longer the processing time between the laser and the workpiece, the more complete the welding, not the faster the better; on the contrary, the faster the better.

Solution:

The welding speed can be scientifically set according to the thickness and type of the material. If it is found that the fusion is not sufficient, the welding speed can be appropriately reduced, the laser irradiation time can be extended, and the molten pool can be fully formed. For occasions where the fusion width needs to be increased, composite processes such as swing welding can be used to improve the fusion effect.

Post-weld characteristics:

The weld is narrow and shallow, the overall fusion is uneven, and it is easy to crack or fall off when manually peeled off.

3. Material and welding power do not match:

The power of the laser welding machine is not suitable for all materials. The power used to weld different materials is different. If the user uses a low power, the welded material will not be firm; for some high-reflective materials, we can increase the welding power, slow down the welding speed and other welding process parameters.

Solution:

Reasonable power can be set for different materials. When welding high-reflective materials, the power can be appropriately increased, the welding speed can be slowed down, and a laser source with a more matching wavelength (such as green light and blue light laser) can be used to improve the absorption rate. In some cases, preheating steps can be added or auxiliary gases (such as argon) can be introduced to stabilize the molten pool.

Post-welding characteristics:

The weld is shallow, there is no obvious fusion mark on the surface, and it is easy to have jump welding or unfused parts, and the peeling is enhanced.

4. Workbench and fixture:

The workbench and fixture are used to fix the material. If the material is not fixed firmly enough, the welding may not be successful, resulting in poor welding and welding missing. For example, nanosecond laser welding equipment requires the two welds to fit completely, otherwise it is easy to have a cold weld. Moreover, we need to customize fixtures to meet the welding needs for those who have difficulty in welding.

Solution:

Special fixtures can be developed for different welded parts, so that the workpieces can fit tightly and not shift. For some precision welding needs, vacuum adsorption, magnetic positioning and other methods can be used to strengthen the fixation. Before welding, the weldment should be repeatedly checked for gaps, especially for thin plates or complex curved parts.

Post-welding characteristics:

The weld is discontinuous, some positions are misaligned or obviously not fused, the weld strength is low, and it is easy to leak or crack.

Laser welding machineis a green and energy-saving laser welding equipment. Compared with traditional welding machines, it has the characteristics of fast welding speed, small heat-affected zone, and flat welding surface. However, improper use will still cause welding defects. Eagle Laser reminds everyone that when using laser welding machine, it is also necessary to follow the welding process and operate reasonably to achieve good welding results.

We specialize in providing industrial automation motion control technology and solutions! (Laser) welding, cleaning, cutting, robot welding machine, and other special CNC equipment motion control systems.