1. Fiber laser continuous platform welding machine has good beam quality, fast welding speed, and firm and beautiful welds. 2. Fiber laser continuous platform welding machine can weld points, straight lines, circles, squares, or any plane figures composed of straight lines and arcs. 3 fiber laser continuous platform welding machine has high electro-optical conversion rate and low energy consumption.

EmailMore

1. Water cooling laser welding machine improves welding speed and quality, solves the problem of insufficient weld width, and reduces material waste. 2. Water cooling laser welding machine adopts an integrated design, beautiful appearance and stable performance. 3. Portable fiber laser welder can realize laser welding of long-distance and large workpieces.

EmailMore

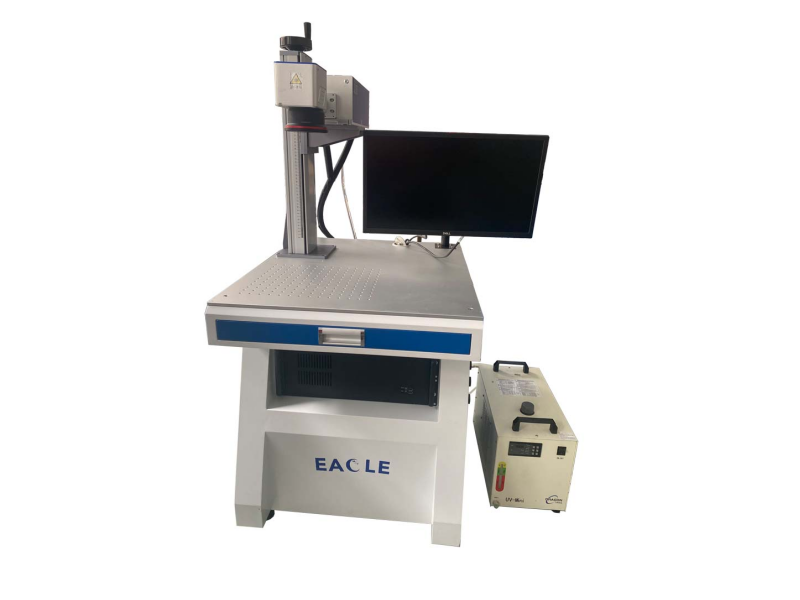

1.Diode end pump laser marker for metal has excellent beam quality and high marking accuracy and consistency. 2.Our diode end pump laser marker for metal has high peak power and can easily cope with the fine processing needs of various materials. 3.Our diode end pump laser marker for metal can achieve high resolution for marking fine graphics and tiny texts.

EmailMore

1. Our precision fiber laser metal cutting machine is produced by our own factory and the quality is guaranteed. 2. We have many years of experience in the production of precision fiber laser cutting machine and have received wide acclaim. 3. Our precision fiber laser cutting machine has many advantages, please contact us for more information.

EmailMore

1.Industrial laser welding robot can load and unload materials manually, or it can cooperate with automated production lines for automatic welding. 2.Industrial laser welding robot is widely used in precision industries such as aerospace, rail transportation, 5g communications, kitchen and bathroom hardware, sheet metal parts, precision instruments, and auto parts. 3. Robotic and handheld laser welding machine can complete any spatial trajectory, and has the characteristics of fast speed and high positioning accuracy.

EmailMore

1. The UV laser wood marking machine is small in size, low in power consumption, stable in operation, and suitable for long-term use. 2. The UV laser wood marking machine supports multiple file format inputs to meet different marking needs. 3. The UV laser wood marking machine can achieve smoke-free and pollution-free operation, which conforms to the modern green processing concept.

EmailMore

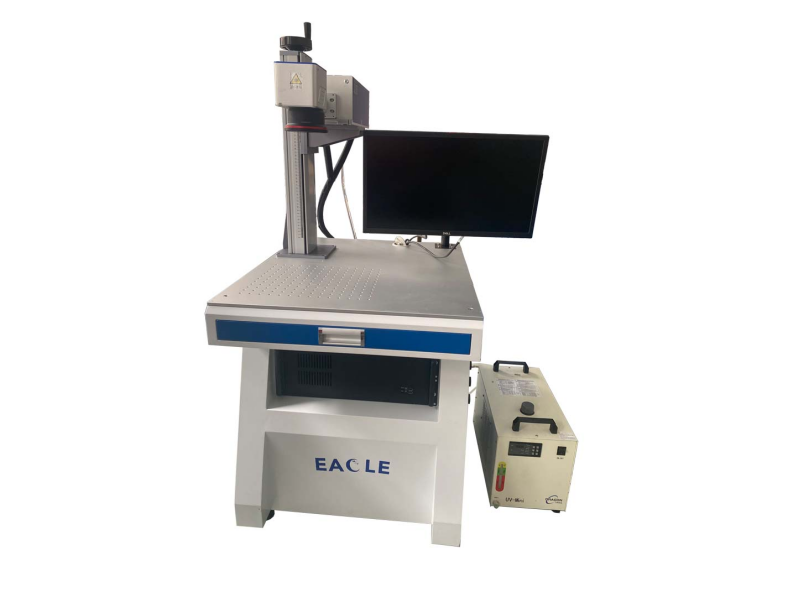

1.3D UV laser marking machine has high precision, clear and accurate marking effect, which can meet the needs of fine processing. 2.3D UV laser marking machine can reach a marking speed of ≤5000mm/s, which is suitable for mass production. 3.3D UV laser marking machine can mark on a variety of materials such as glass, silicone, plastic and electronic components.

EmailMore

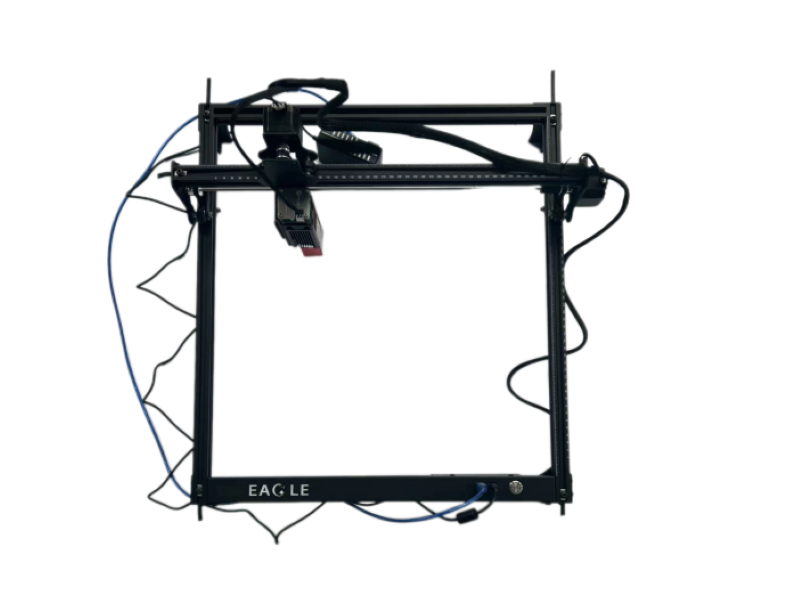

1.Diode end pumped laser marking machine adopts advanced blue laser technology, with the characteristics of efficient marking and exquisite processing effect. 2.Diode end pumped laser marking machine has a shorter wavelength, which is suitable for high-precision processing of complex patterns and tiny fonts. 3.Diode laser engraver adopts an integrated design, with a light body and simple installation and operation.

EmailMore

1. The handheld fiber laser marking machine is lightweight and portable, which is convenient for handheld operation. 2. The handheld laser engraver for metal is suitable for various scenes and working environments. It can be used for fixed indoor office and flexible outdoor operation. 3. The handheld laser engraver for metal is equipped with an emergency stop function, which is highly safe.

EmailMore

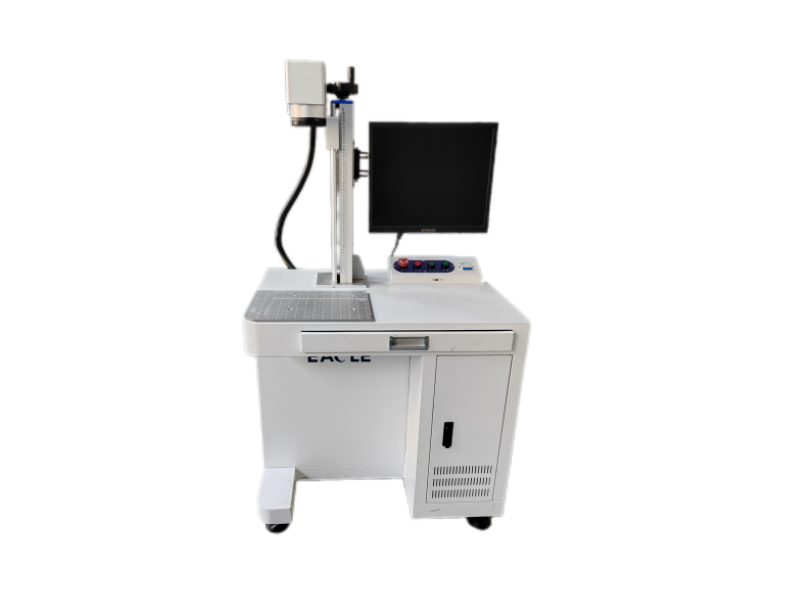

Laser fiber marking machine uses laser beam to print permanent marks on the surface of various materials. The effects of laser fiber marking machine are mainly: 1. Laser fiber marking machine uses laser light energy to evaporate the surface of the target material to expose the deep layer of the material. 2. Laser fiber marking machine uses laser light energy to cause chemical and physical changes in the surface material to "carve" the required pattern and text. 3. Fiber laser engraver uses laser light energy to burn off part of the material, thereby showing the required pattern and text to be etched.

EmailMore