01-07/2026

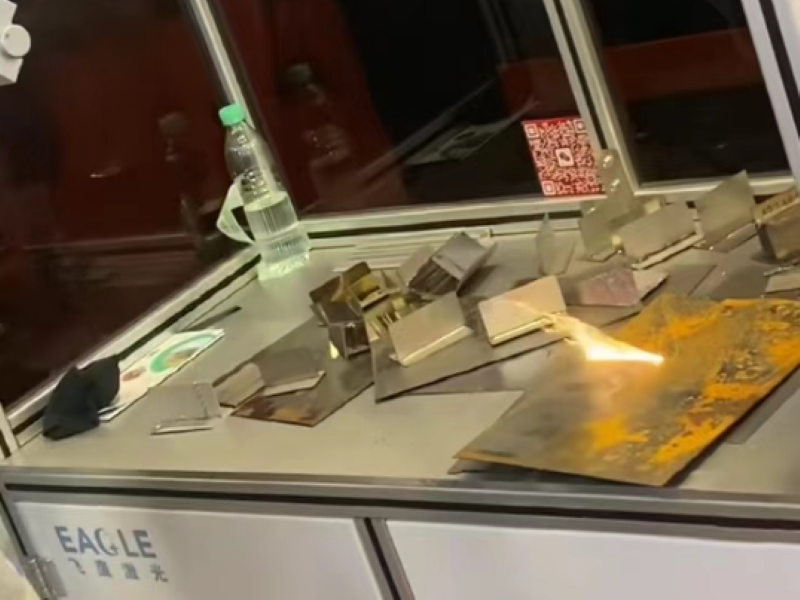

Simply put, a handheld laser cleaning machine uses lasers to achieve cleaning, also known as laser cleaning. Laser cleaning utilizes pulsed laser irradiation to clean the surface of an object. The adhering substances on the surface absorb the laser energy, causing thermal expansion and reducing the adhesion between the substrate and the adhering substances. Simultaneously, by outputting high-frequency pulsed laser energy, high-frequency vibration impacts are generated, causing the adhering substances to shatter and detach from the substrate. Handheld laser cleaning machines can remove paint from precision areas precisely where needed, without requiring covering or moving protective tools during each operation.