07-15/2025

Today, we continue the discussion on the industrial chain and market size of China's laser processing equipment manufacturing industry in the previous issue, and take a look at the

current status of the industry development.

Current status of the development of the laser processing equipment manufacturing industry:

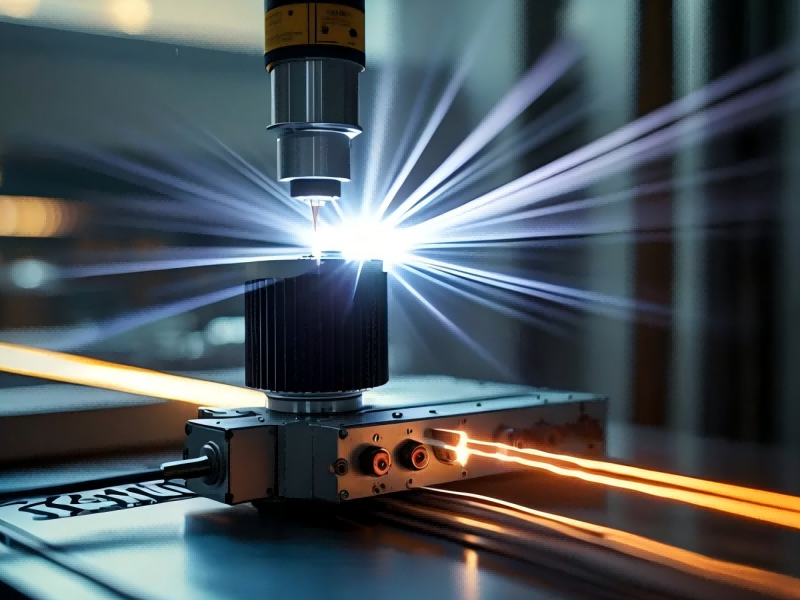

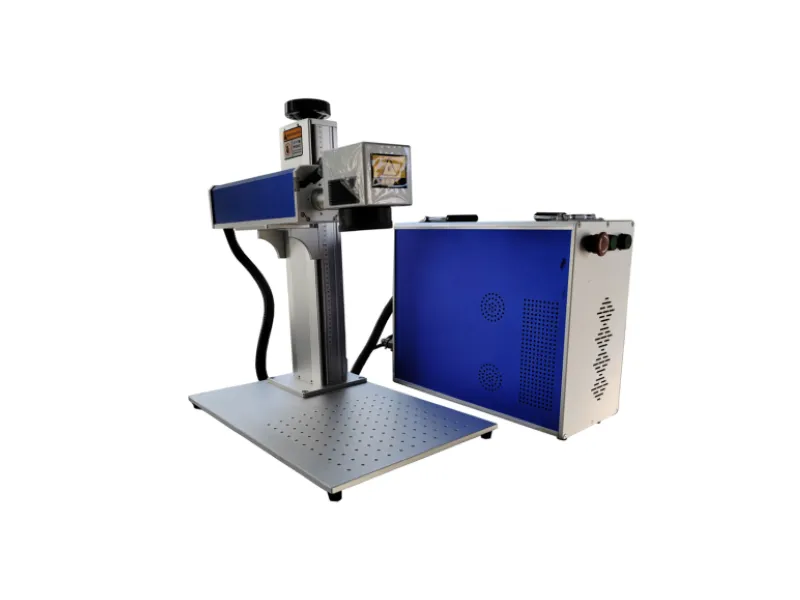

In recent years, influenced by factors such as macroeconomic development, manufacturing industry upgrading, and national policy support, my country has become the world's largest industrial laser market to date. At the same time, with the proposal of "Made in China 2025", the continued growth of China's economy and the development of China's manufacturing industry have a strong driving effect on the market demand of the laser processing equipment industry, and have created favorable conditions for technological innovation in the laser processing equipment industry. In recent years, the localization rate of the industry has increased, the downstream fields of the industry have developed rapidly, especially the significant growth in sheet metal cutting demand, and the vigorous development of the microelectronics manufacturing industry have driven the rapid growth of the market size of my country's laser processing equipment industry. Data shows that the market size of China's laser processing equipment industry in 2024 will be about 89.9 billion yuan. From the perspective of market structure, laser cutting equipment is the largest sub-segment of laser processing equipment in my country, with a market share of about 39.27%, followed by laser welding equipment and laser engraving equipment, with market shares of 15.93% and 11.77% respectively.