05-28/2025

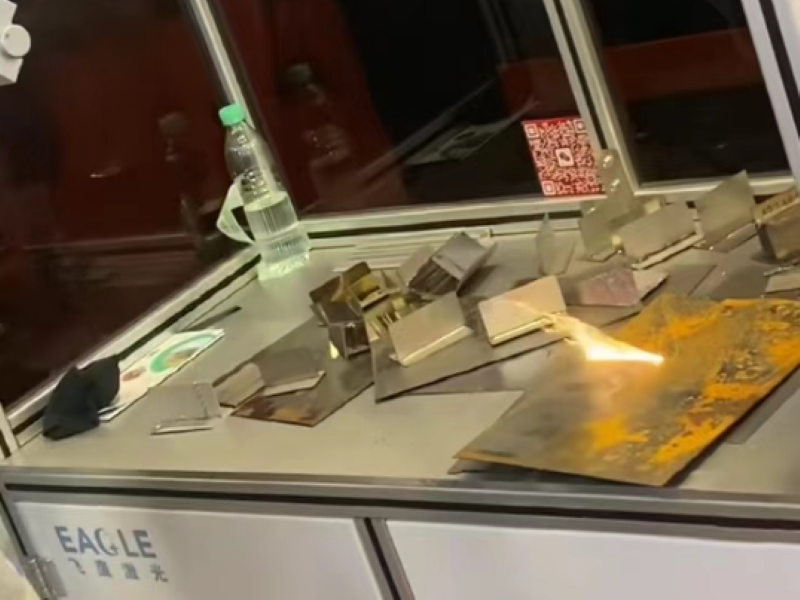

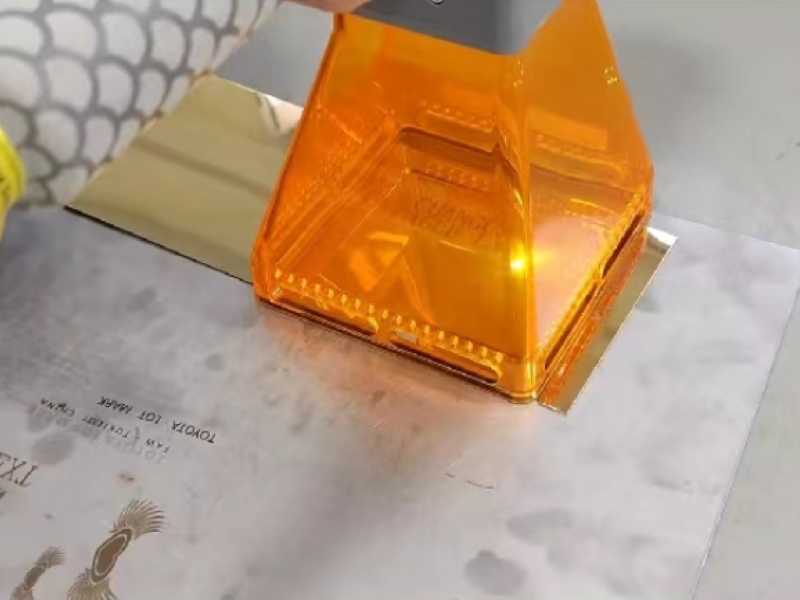

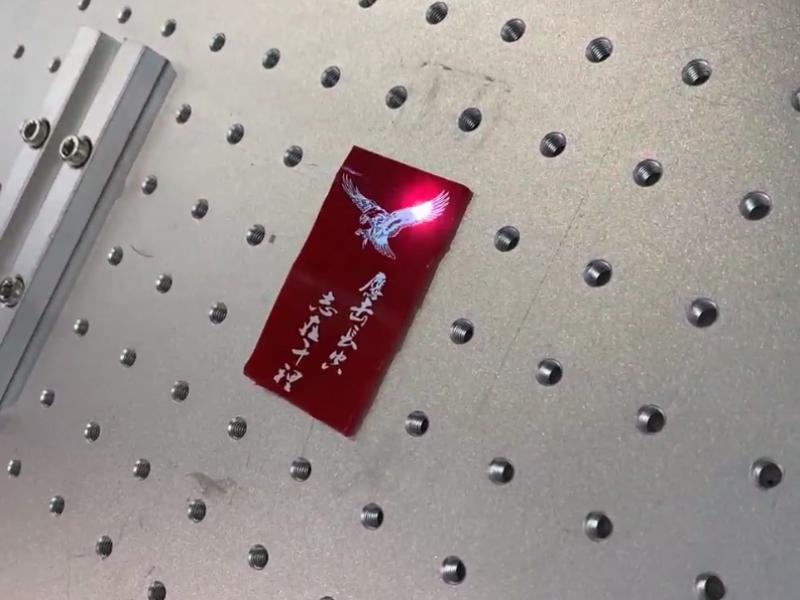

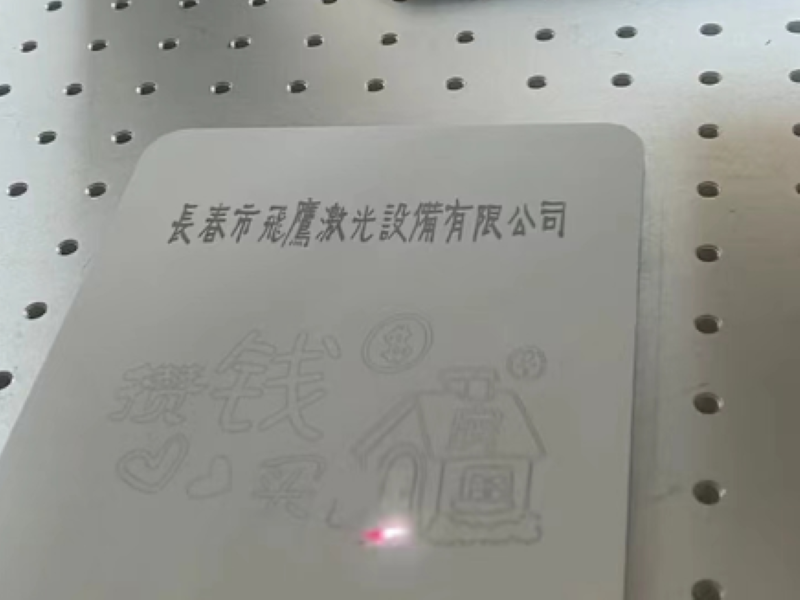

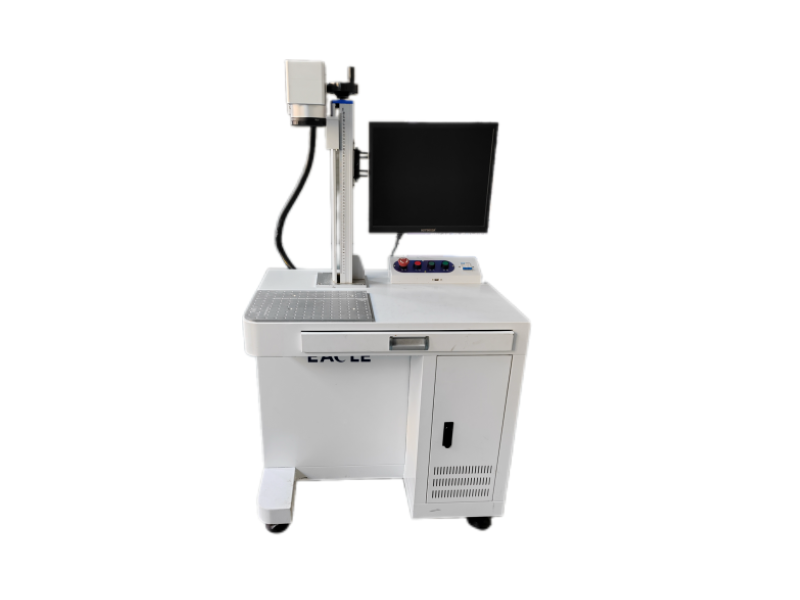

What is a portable handheld laser cleaning machine? Experience sharing from the perspective of Eagle technicians

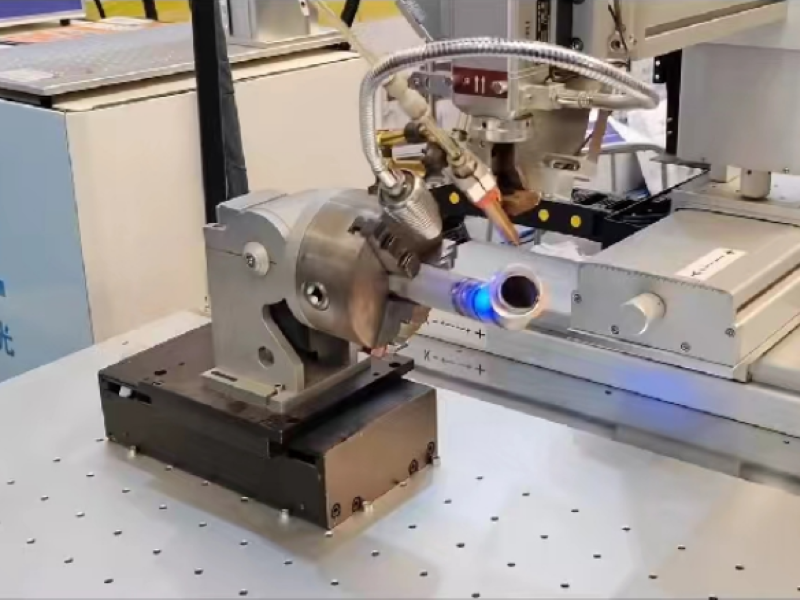

When cleaning surface contaminants, is it possible to do so without harming the earth or using strong chemicals? Our Eagle technicians have long been concerned about this issue and have actively invested in the research and development and practice of laser cleaning technology. We believe that the portable handheld laser cleaning machine is a truly environmentally friendly solution that can protect materials while greatly reducing the waste and pollution caused by traditional processes.