Brand protection isn't just a matter for large companies—it concerns every business that takes product quality and customer trust seriously. Some products once renowned for their high quality have lost market share to counterfeiters, even leading to customer complaints and a crisis of trust.

So, how can companies proactively defend themselves? One answer lies in anti-counterfeiting marking technology.

I. Why are anti-counterfeiting markings so important?

Counterfeit products not only endanger consumer health and a company's reputation but can also lead to legal action, decreased sales, and even a collapse in brand value. Therefore, choosing the right anti-counterfeiting marking method is the first step in ensuring product authenticity and legitimacy.

II. Main Categories of Anti-Counterfeiting Technology: Chemical vs. Physical

From a technical perspective, there are currently two main anti-counterfeiting approaches:

Physical markings, such as laser etching, inkjet coding, and raised printing. These features can be detected visually or by touch, making them suitable for situations requiring rapid manual inspection.

Chemical markings, such as UV inks and DNA tags, typically require specialized equipment to read and are extremely difficult to replicate. They are suitable for high-value, high-risk products.

In a recent custom marking solution we provided for a company, they adopted a dual strategy: using dot-matrix inkjet coding for product encoding on the exterior and UV ink-embedded covert marking on the interior for customs clearance and tracking. This approach increases the cost of counterfeiting.

III. Overview of Mainstream Anti-Counterfeiting Marking Technologies:

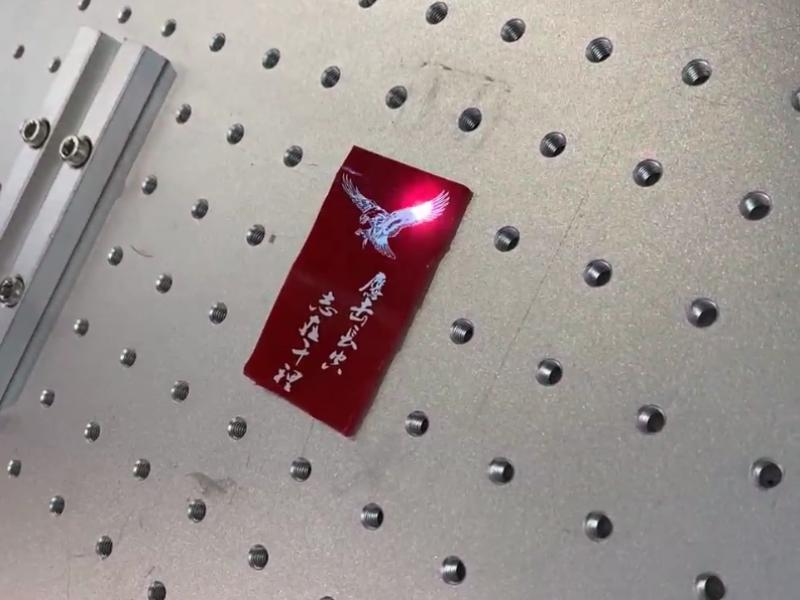

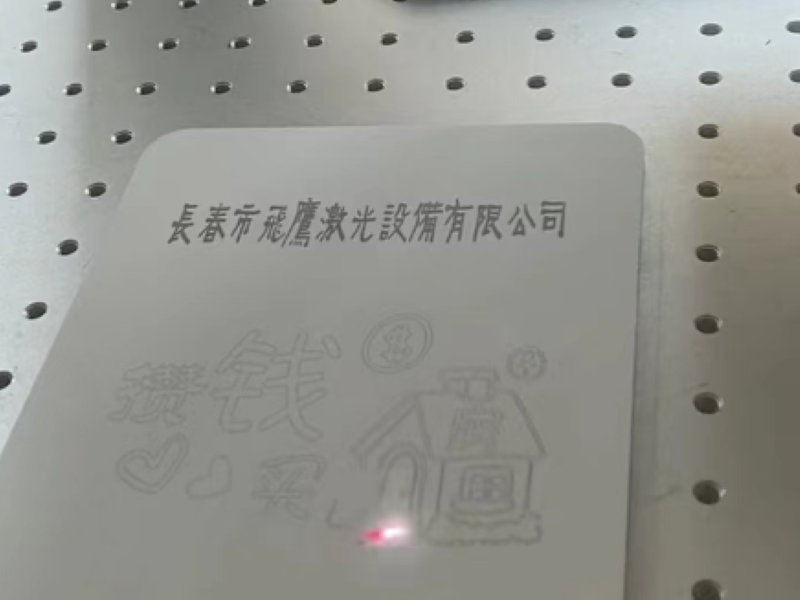

1. Fiber Laser Marking Machine:

Laser marking is popular in industries such as electronics, automotive, and medical devices due to its high precision and resistance to tampering. Many of our clients choose portable fiber laser marking machines for permanent marking on metal products.

2. UV Ink Printing:

UV ink is an invisible marking method that can only be read under specific light sources. It is suitable for industries such as tobacco, cosmetics, and food. It is environmentally friendly and fade-resistant, making it a green printing option.

3. Holograms and Watermarks:

These are widely used in bills, certificates, and packaging. They have a strong visual impact and are highly recognizable to consumers. However, they are more expensive and are suitable for mid- to high-end products.

4. DNA Marking:

Although costly, they offer high uniqueness and legal validity, making them commonly used in luxury goods and high-tech industries. At an overseas exhibition, we saw a brand combining DNA coding with packaging materials, a highly innovative approach.

5. Microtext and Microdots:

Microscopic information, invisible to the naked eye, is embedded into the surface of packaging or products, requiring microscopic tools for identification. This technology is suitable for applications requiring anti-counterfeiting and precise traceability.

IV. Which Industries Rely Most on Anti-Counterfeiting Marking?

Almost all industries face the threat of counterfeiting, but the following sectors are particularly reliant on fiber laser marking machine technology:

| Industries | Application Scenarios |

| Pharmaceuticals | Drug batch number, dosage identification, and tamper prevention |

| Tobacco and Alcohol | Legal sales verification and tax tracking |

| Electronics | Parts source traceability and tamper prevention |

| Medical Equipment | Unique coding for surgical instruments |

| Automotive Parts | DPM direct marking for authenticity verification |

V. How to Choose the Right Fiber Laser Marking Machine for Anti-Counterfeiting?

In practice, we have helped many clients select marking machines. Here are some tips from our experience:

Marking Type Requirements: For example, if you need invisible marking, choose a UV fiber laser marking machine. For permanent marking, laser is recommended.

Material Compatibility: Choose a fiber laser marking machine for metals and a CO₂ laser or inkjet printer for plastics.

Identification Method: Is machine readability required (OCR/QR code/barcode)?

Scalability: Does it require networking, tracking, or integration with an ERP system?

Stability and After-Sales Service: Imported brands are more expensive but reliable, while localized service is more suitable for large-scale, long-term use.

We recommend that customers conduct sample marking tests before selecting a model. For example, our portable fiber laser marking machine is suitable for high-volume marking and flexible mobile operation, balancing cost and efficiency.

Anti-counterfeiting isn't just a technical issue; it's also part of brand strategy. A tiny mark represents a commitment to customer trust. While companies may not pursue the most expensive options, they should never overlook the right solution.

If you're considering how to enhance your product's anti-counterfeiting capabilities or have questions about selecting a marking technology, please contact our engineering team.