Laser welding is a field of metalworking technology that uses lasers. It is widely used in various industrial fields, including automobiles, precision equipment, electronics, aerospace, and medicine. This article will introduce the basics of laser welding, particularly in sheet metal processing, among its many applications.

What is laser welding? (Characteristics)

First, the word "laser" is derived from the initial letters of the term "light amplification by stimulated emission of radiation."

While it may seem a bit complicated at first, it's generally understood as "artificial light." Compared to ordinary light like sunlight and lighting we see every day, laser light, as artificial light, has the characteristics of constant wavelength, phase, and direction. By adjusting and utilizing these three key factors, collectively known as "coherence," lasers can be used in various processes.

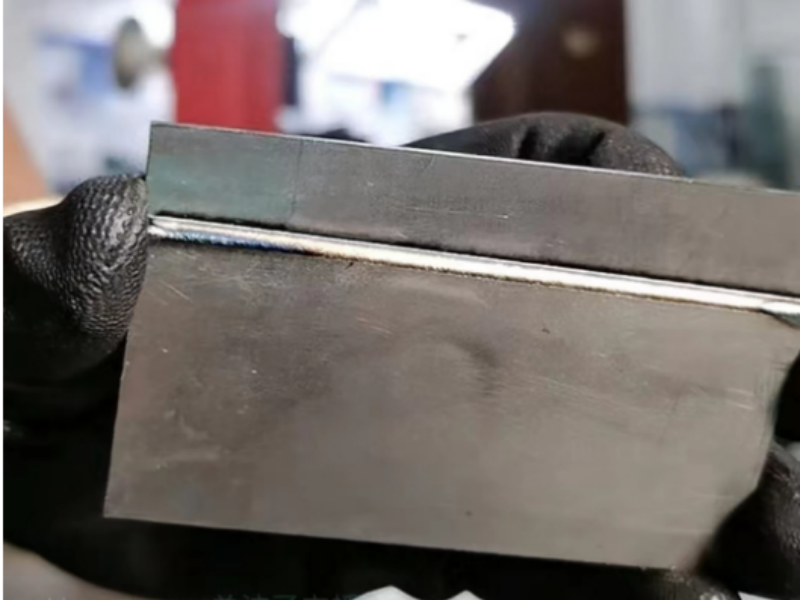

Laser welding is a processing method that focuses laser light, irradiating an object with it, locally melting and solidifying the metal to form a joint. The introduction of laser welding into sheet metal processing offers advantages over conventional arc welding, such as easier thermal deformation control, easier control of welding conditions, and less noticeable weld beads.

What is the principle of laser welding?

In laser welding, a laser oscillator generates laser light, which serves as a heat source. This light is then amplified and transmitted using optical fibers, initially delivering the light to the vicinity of the workpiece. This stage requires a laser processing head. A lens is installed within the laser processing head to focus the transmitted laser light into a state suitable for processing. By focusing the light with the lens, the light energy is concentrated on a smaller area, achieving higher energy for melting the metal. To prevent oxidation of the molten metal, a shielding gas such as argon or nitrogen is typically blown during welding.

What types of laser welding are there?

Let's look at the types of laser welding suitable for manual welding in sheet metal processing. Portable laser welding machines using YAG lasers first became popular in Japan in the 1990s. Since then, the Japanese sheet metal industry has long considered "laser welding machines equal YAG lasers." However, with the release of fiber laser welding machines in the mid-2010s, fiber lasers have become the mainstream of portable laser welding machines. Portable welding devices using disk lasers are also available.

Manual welding using fiber laser welding machines:

YAG laser welding:

YAG is a crystal called yttrium aluminum garnet. YAG lasers generate laser light by irradiating YAG crystals with intense light. YAG lasers have a wavelength of 1064nm, which is easily absorbed by metals. Therefore, they can melt metals with relatively low energy, making them suitable for laser welding. On the other hand, laser generation requires a flash lamp to flash, and the high heat generation necessitates a chiller to cool the oscillator and torch. This results in high power consumption, resulting in less energy available for processing compared to the electricity used, leading to occasional incomplete welds. Maintenance costs for consumables such as cooling water and lamps are also high, a significant drawback.

Fiber laser welding:

Fiber lasers use optical fibers to amplify and transmit the generated excitation light. They have a wavelength of 1070nm, which is easily absorbed by metals. Among lasers, they have the highest energy density, making it easy to focus the beam, and their ability to achieve deep penetration in metals is a major advantage. Compared to YAG lasers, they offer many advantages, including deep penetration, low operating costs, and virtually no adjustment or maintenance effort and cost, leading to their rapid adoption in recent years. While fiber lasers offer high power and efficiency, excessive power can pose a risk to operators in manual sheet metal welding, so they are typically limited to around 1kW. For those seeking higher power and greater penetration depths, mechanical or robotic welding can be considered.

Disk Laser Welding:

Disk lasers use a disk-shaped YAG crystal to amplify the generated excitation light, which is then transmitted via optical fiber. The German company Quicken successfully achieved high power and stabilization, leading to widespread adoption of this laser for industrial use. In recent years, its potential has been re-evaluated, and new applications are being actively developed. While there are no standalone systems in Japan capable of manual welding using disk lasers, users of Quicken laser cutting machines can optionally purchase a manual welding torch.

Advantages and Disadvantages of Laser Welding:

Laser welding, used in sheet metal processing, has the following advantages compared to the widely used TIG welding.

Advantages:

Reduced thermal deformation, even with thin sheets.

Because TIG welding produces shallow penetration and a large heat-affected zone, it delivers high heat input to the metal, resulting in significant thermal deformation. Managing this thermal deformation depends heavily on the craftsman's skill, and this is the most challenging aspect of TIG welding. Laser welding, on the other hand, uses a focused laser, concentrating high energy into a small focal point to melt the metal. This results in a narrower weld penetration and a smaller heat-affected zone, making thermal deformation less likely. Furthermore, the laser's frequent on-and-off "pulsing" cycle repeats the melting and solidification process several to dozens of times per second, further minimizing deformation.

Sufficient Weld Strength:

Laser welding produces thinner weld beads, which can sometimes lead to concerns about insufficient strength. However, due to its deep weld penetration, the weld possesses sufficient internal strength compared to its external appearance. Laser welding involves minimal alloy melting and solidification, resulting in less fracture. Strength tests conducted at an industrial testing facility have confirmed that laser welding exhibits strength exceeding that of TIG welding.

Reduced Processing Time:

Laser welding generates low heat input and is less likely to cause deformation, significantly reducing the time required to eliminate this deformation. Furthermore, laser welding essentially welds the base metal, eliminating the need for grinding weld protrusions. Furthermore, as long as the processing conditions are met, weld seam burn is virtually nonexistent, potentially eliminating the need for electrolytic grinding. This reduces the processing time, which was previously a difficult task, leading to improved production efficiency and lower manufacturing costs.

Easy to Manage and Operate Welding Conditions:

Some laser welding machines allow welding conditions to be registered and recalled as methods, making them easy to manage and reproduce. In this case, simply having an experienced operator specify the conditions makes it easy for an unskilled welder to replicate them. This allows unskilled welders to weld thin sheets, freeing experienced welders to focus on higher-value-added tasks, contributing to improved overall welding efficiency.

Disadvantages:

Poor Gap Handling:

Laser welding focuses laser energy on a very small spot, approximately 0.1 to 0.6 mm in diameter, to melt the metal. This property makes it difficult to weld if there are gaps. For models with a spot diameter of 0.1 mm, a gap as small as 0.1 mm will cause the laser to pass through it, preventing welding. Therefore, measures such as improving bending process accuracy and installing jigs are necessary.

Weakness to Overlay Welding:

Laser welding excels at welding base metals but not overlay welding. Not only may the laser energy not fully reach the base metal where the electrode is melted, but it can also be difficult to precisely align the weld point, electrode, and focal point, potentially preventing sufficient strength. If overlay welding is indicated in the drawing, consider whether laser welding is appropriate. Conversely, if laser welding is desired for strength and aesthetics, it is best not to include instructions for overlay welding.

Required Safety Measures:

Misuse of lasers can lead to serious accidents. Therefore, all laser products have safety specifications specified in the JIS "Laser Product Safety Standard." All manual welding devices using lasers are classified as "Level 4," the highest risk level, and manufacturers implement various safety measures. Please ensure proper use according to the specifications and operating instructions, such as establishing a laser control area, using a welding mask/goggles specifically designed for laser welding, using a portable welding torch with an included safety device, and properly managing the key to the device.

Tips for Laser Welding:

Laser welding offers both strong and aesthetically pleasing welds. It's a joining method with many advantages, such as low distortion for thin plates and easy condition management. However, it also has disadvantages, such as poor seam handling and poor cladding performance. Tips for effectively utilizing laser welding include:

Improve the accuracy of the bending process, set up jigs, and weld after achieving a seamless state.

Preparing for the processing conditions and registering the method with an experienced person makes it easier for even unskilled workers to replicate the process.

Maintaining drawings based on conventional processing methods like TIG welding and simply switching to laser welding can be challenging. Considering design changes is sometimes necessary.

To maximize the strength and aesthetic advantages of laser welding, it's recommended to design with laser welding in mind from the outset.

The greatest advantage of laser welding is its ability to weld thin plates with low distortion. Furthermore, even unskilled workers can achieve this, potentially significantly improving welding processes that previously relied on the skill of craftsmen. Understanding its drawbacks and addressing them appropriately will reveal its advantages. Take advantage of the advantages of laser welding to the maximum extent possible.