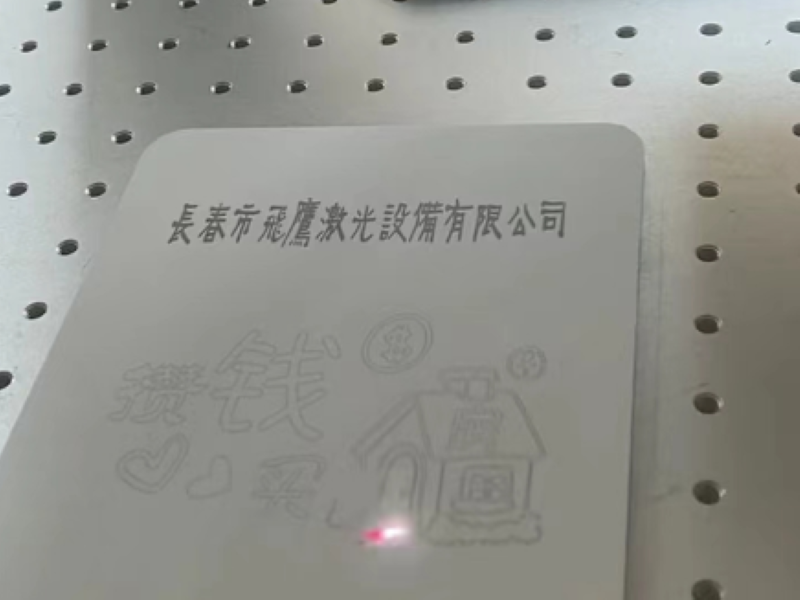

Step-by-step guide to laser engraving stainless steel:

Our practical experience has shown us that achieving ideal engraving results requires the following steps:

Material selection: Choosing the right grade of stainless steel is crucial. 304 is suitable for most general needs, while 316 is more corrosion-resistant and suitable for medical or marine environments.

Surface preparation: Cleaning is essential before laser engraving stainless steel. Oil and dust can affect laser energy transmission and reduce effectiveness. We typically use alcohol to wipe the surface to ensure it is dry.

Securing the workpiece: When laser engraving stainless steel, the workpiece must be stable. We typically use specialized fixtures to minimize vibration and maintain an accurate engraving path.

Design file preparation: Vector files are preferred, with .plt format offering the best compatibility. Avoid overly complex designs and maintain clear lines to ensure a sharp, layered engraving.

Laser parameter adjustment:

The power, speed, and frequency should be adjusted flexibly based on the material and design details. Experience has shown that too low a power results in shallow lines, while too high a power may damage the material. Slow speeds produce sharper details but reduce efficiency. Focus adjustment must be precise; the focal point is crucial for engraving quality.

Engraving Monitoring and Finishing: Observe the engraving process continuously to ensure accuracy. After completion, gently wipe with a soft cloth to remove residue and protect the engraved surface.

Importing and Preparing Design Files:

The quality of your design file directly determines the accuracy and aesthetics of your laser engraving of stainless steel. We recommend:

Use compatible software (such as CorelDraw) to create or import your design. Ensure the design file is in the correct format; graphics and logos are typically in .plt format.

Text and numbers can be entered directly into the laser machine's software. Please follow the steps below to prepare your design:

1. Create Your Design: Use CorelDraw to draw a graphic, logo, or any complex design.

2. Export Your Design: Save your design in .plt format, suitable for importing into the laser machine's software.

3. Load the File: Import the .plt file into the laser engraver's software to ensure it is ready for precise, clear engraving.

Setting Up the Laser Engraver:

We typically make the following adjustments based on the specific task:

Power: Adjust based on material thickness and desired engraving depth. Insufficient power results in shallow engraving; excessive power can easily cause scorching.

Scanning Speed: When intricate details are used, slow down the speed to ensure clarity; simple designs can be accelerated for increased efficiency.

Focus Adjustment: Precise calibration is required to focus the laser beam on the material surface and ensure sharp details.

MOPA Laser Parameters: Pulse width and frequency adjustment enable color engraving to meet individual customer needs.

Five Practical Tips for Laser Engraving Stainless Steel:

Through years of project experience, we have summarized the following practical tips:

Clean and Simple Design:

Choose clear, legible fonts and avoid complex embellishments. Nameplate information should highlight the core content to ensure legibility from near and far.

Enhance Contrast and Engraving Depth:

Adjust the laser power to achieve appropriate engraving depth, enhancing the contrast between the text and the underlying surface, ensuring wear resistance and legibility.

Adequate Size:

Text height is recommended to be at least 1.5 mm, and details should be minimal to avoid broken lines or blurring during engraving.

Vector Design and High-Resolution Images:

Use vector files to ensure sharp edges and avoid pixelation in bitmaps that can affect engraving quality. Resolution must be at least 300dpi.

Strict Sample Testing:

Pre-production samples are produced to verify the engraving results and ensure that the design matches the process parameters.

Laser engraving stainless steel offers numerous advantages and details, accumulated through experience gained in daily work. If you have specific needs or questions, please feel free to contact us. We will provide tailored advice to help you achieve high-quality engraving results.