10-31/2025

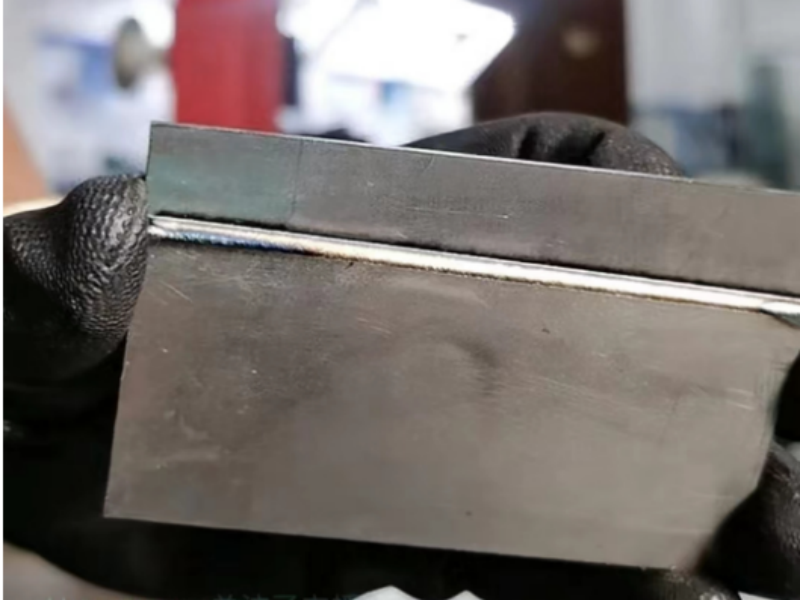

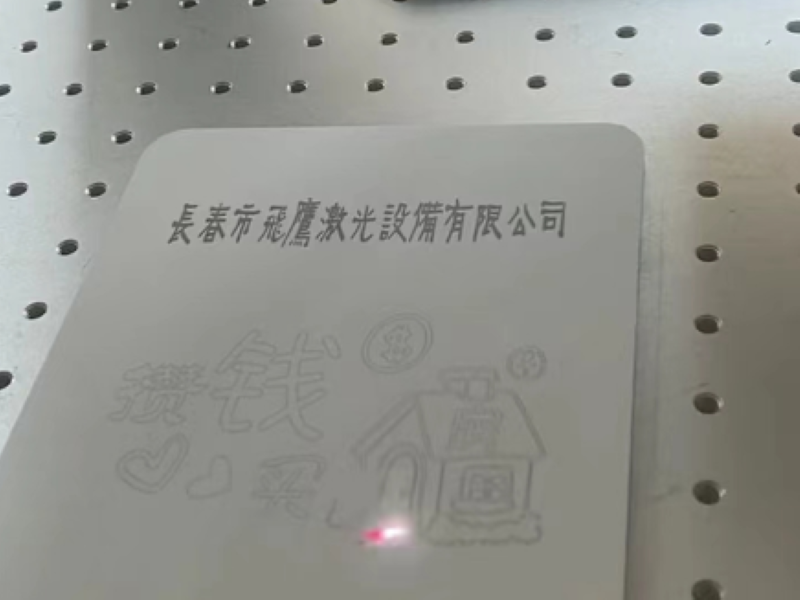

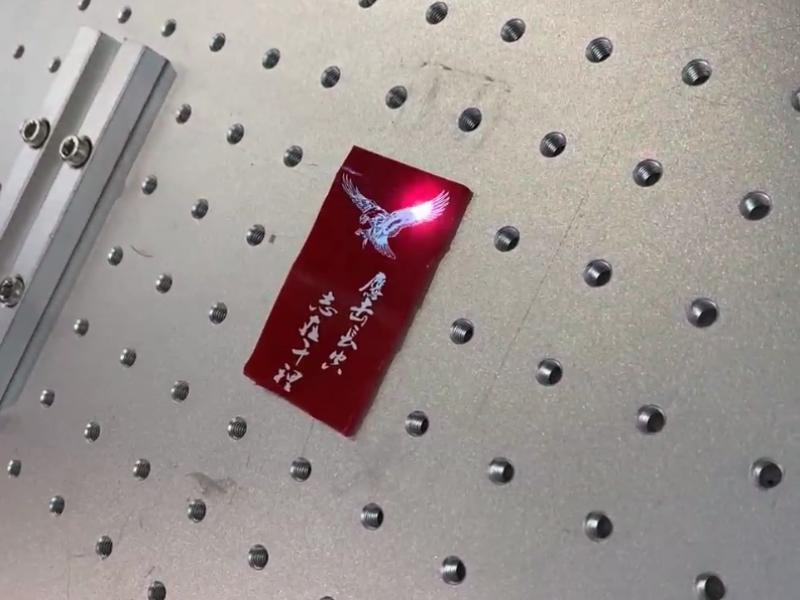

In modern industrial production and infrastructure construction, steel structures are widely used due to their high strength, light weight, and convenient construction. However, the surface of steel structures exposed to complex environments for a long time can easily rust, which not only affects the aesthetics of steel, but also weakens the stability and durability of the structure. Regular rust removal and maintenance have become a key part of ensuring the performance of steel structures. Although traditional rust removal methods such as mechanical sanding, sandblasting and rust removal, chemical pickling, etc. have long occupied a dominant position, they generally have disadvantages such as low efficiency, high labor intensity, damage to the substrate, and serious environmental pollution. So today let's take a look at what kind of surprises our Feiying Laser's handheld laser cleaning and rust removal function will bring you!