01-05/2026

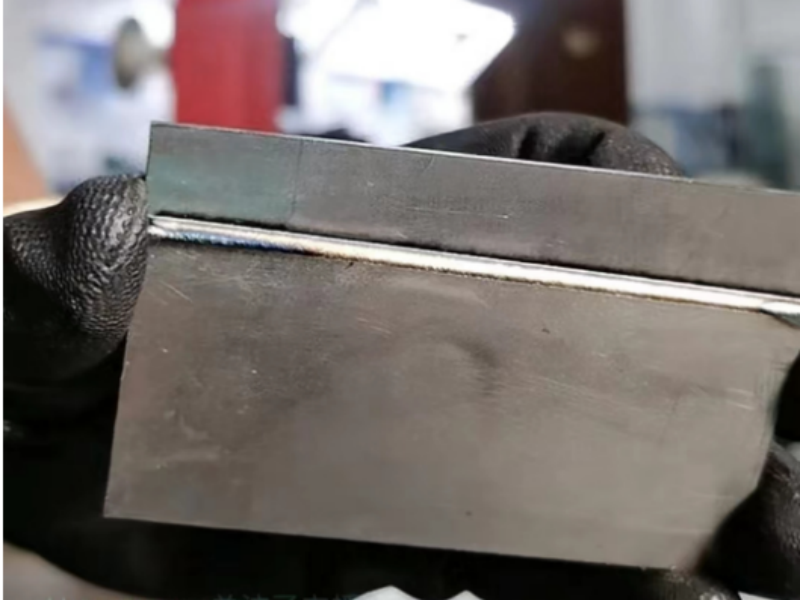

Under the development trend of the new energy vehicle industry pursuing safer, lighter, and more efficient, the welding quality of core components directly determines the performance and safety of the vehicle. From the sealing of the battery tray to the strength of the lightweight structure of the body, the traditional welding process is gradually difficult to meet the stringent requirements-large welding deformation, insufficient weld strength, low operating efficiency and other issues have become a bottleneck for manufacturers to improve production capacity and quality. With the advantages of precision, high efficiency and stability, fiber laser welding machine is becoming a key equipment for the manufacture of core components of new energy vehicles, providing a new path for the industry to break through processing problems.